*This post is a pillar post for radiation shielding. Multiple in-depth blog posts have been linked throughout this article for more information on specific topics.

Table of Contents

ToggleIntroduction

In various industries and applications, radiation shielding plays a critical role in protecting human health and ensuring safety.

And while it’s extremely important to have proper radiation shielding, we also understand that it can be extremely confusing and intimidating for individuals who may be new to the industry, or those who could just be looking to erect shielding for their business.

Although AVM Group has a vast array of blogs covering specific aspects of the radiation shielding ecosystem, we created this comprehensive guide to serve as a valuable ever-green resource covering all aspects of radiation shielding, providing insights, best practices, and expert advice.

This guide will touch on each aspect mentioned briefly, and will link to specific content on our site that goes much further in depth.

Make sure to bookmark this blog for any future questions you may have.

Without further ado, let’s begin.

The Importance of Radiation Shielding in Various Industries and Applications

We touched on it briefly in the introduction to this guide, but it really is important to fully have a grasp on why proper radiation shielding is so important.

Radiation shielding isn’t just for one small group of businesses.

This shielding is essential across multiple industries and applications, including medical, industrial, research, aerospace, and defense.

By effectively mitigating radiation hazards, shielding safeguards personnel, the environment, and sensitive equipment.

Plus, radiation shielding is commonly utilized as a tool for quality control, and for expanding business operations by bringing in and controlling the radiographic testing (RT) process in house.

Let’s talk more about the purpose of this guide, and what you can expect to find throughout it.

Overview of This Guide

Like we mentioned before, this guide aims to be an all-encompassing resource for understanding radiation shielding.

We’ll talk about the different types of radiation that exist (along with their hazards), the different type of radiation shielding material options that exist, how we go about designing safe and effective radiation shielding for our clients, the industries that utilize radiation shielding (along with examples), how to properly maintain your newly constructed shielding, and the latest and greatest for shielding.

Understanding Radiation and its Hazards

Now that you have a good understanding of what this guide is about, we can help provide a great understanding of the different kinds of radiation and the potential hazards they pose.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of the shielding industry with our weekly e-newsletter.

The Different Types of Radiation

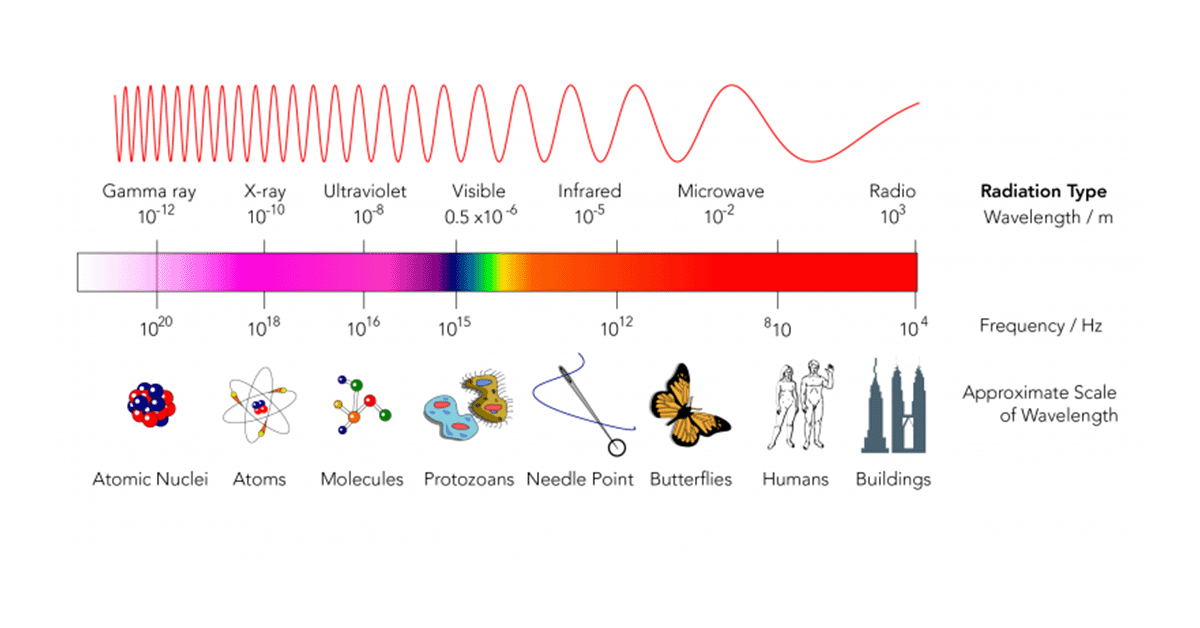

Radiation can be broadly classified into ionizing and non-ionizing radiation.

Ionizing radiation, including X-rays, gamma rays, and alpha and beta particles, possesses sufficient energy to ionize atoms or molecules. This means that, according to the CDC, “intense exposures to ionizing radiation may produce skin or tissue damage”. This is the type of radiation that requires radiation shielding.

Non-ionizing radiation, such as radio waves and visible light, lacks this energy level. This type of radiation is generally harmless due to the fact that it doesn’t carry enough energy per quantum (photon energy) to ionize atoms or molecules. It doesn’t require radiation shielding.

If that’s a bit too confusing for you, don’t worry. Check out this chart for a visual representation of what we just covered.

What happens if you get exposed to too much ionizing radiation for too long?

Understanding the Health Risks Associated with Radiation Exposure

Exposure to ionizing radiation can have detrimental effects on human health, including DNA damage, increased risk of cancer, and acute radiation syndrome.

The severity of these risks depends on factors like radiation dose, exposure duration, and the body part exposed.

However, this isn’t a comprehensive list of common radiation sickness symptoms.

For that and more, check out our guide on how to protect yourself from radiation.

Since the consequences of over-exposure to radiation is so bad, are there regulations in place to prevent this?

Regulatory Guidelines and Standards for Radiation Protection

Regulatory bodies worldwide have established guidelines and standards to ensure radiation protection.

These regulations prescribe safe radiation limits, permissible exposure levels, and requirements for shielding designs and measurements.

This includes, but is not limited to, the EPA’s FGR (federal guidance report no.) 1-15, the U.S NRC’s Part 20 standards, and other guidelines outlined by the National Library of Medicine.

Now, let’s look at arguably the most important aspect of your shielding, the materials you’ll be using to block radiation.

Types of Radiation Shielding Materials

Effective radiation shielding relies on utilizing appropriate materials that possess high attenuation properties for specific radiation types.

Attenuation is described as the reduction of force, effect, or value of something. In this case, that “something” is harmful ionizing radiation.

What are some of the most common radiation shielding materials?

Overview of Common Radiation Shielding Materials

Lead, steel, concrete, and sand are among the most commonly used radiation shielding materials. Each material has unique properties that make it suitable for specific radiation types and applications.

Of course, almost any material can be used to shield radiation in shielding rooms/vaults and radiation shielding doors based on their attenuation factor, but the materials we listed are the industry standard, and make the most sense from a construction and use standpoint.

Plus, these materials have better attenuation properties that make them more attractive for shielded rooms and doors.

If you want more info on sand radiation shielding, click here.

Check out this article comparing lead to concrete for radiation shielding.

Properties and Effectiveness of Different Materials

With radiation, each type requires a different shielding material.

For example, lead, concrete, and sand offer exceptional attenuation for gamma rays and X-rays.

Whereas polyethylene and concrete are better for attenuating neutron radiation.

Understanding these material properties helps in selecting the most suitable shielding and cost-effective option for a given application.

Considerations for Selecting the Appropriate Shielding Materials

Several factors influence the selection of the appropriate shielding material, including the type and energy of radiation (like we just mentioned), required shielding thickness, cost considerations, and structural limitations of where the shielding is being constructed.

A comprehensive evaluation ensures optimal shielding performance while considering budgetary constraints. This is always done within the physics report completed prior to breaking ground at the job site.

Advancements in Radiation Shielding

Like every other industry, the radiation shielding market is advancing.

Ongoing research and technological advancements have led to the development of new radiation shielding technologies that offer cost-savings, reduced weight, ESG and LEED compliance, and enhanced convenience in shielding applications.

These new technologies are extremely viable and are emerging in the radiation shielding marketplace.

Now that you’ve got a fundamental scope of the shielding materials you’ll be selecting from, let’s talk a bit about how we (AVM Group) design our shielding safely and effectively.

Designing Effective Radiation Shielding Solutions

In the coming paragraphs, we’ll dive into each of these factors.

Conducting Radiation Surveys and Risk Assessments

Prior to designing your radiation shield, you’ll need to conduct a radiation survey and risk assessment to help identify potential hazards and quantify radiation levels.

This crucial step ensures that the shielding design meets the specific needs of the facility or application, and all state and local requirements and regulations.

These surveys and assessments are always conducted under the umbrella of a physics report that our in-house team of physicists develops specific to each project.

Collaboration with Radiation Safety Experts and Professionals

After you’ve completed an approved physics report, it’s time to loop in the rest of the team that will be handling the design and build portion of the project.

It is absolutely crucial that you continue to work with radiation shielding experts. Preferably, work with the firm that developed your physics report for project continuity. Not working with a team of experts could cause safety and financial problems.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of the shielding industry with our weekly e-newsletter.

Optimizing Shielding Design for Different Radiation Sources and Exposure Scenarios

In order to optimize your radiation shielding design, it’s vital to tailor solutions to specific radiation sources and exposure scenarios.

Different radiation sources can require different shielding approaches to ensure optimal protection.

Different machines/processes radiate different types/amounts of radiation, meaning every shielding situation should be treated uniquely.

If you are working with an experienced radiation shielding team, they will have already accounted for these variables in their design.

But, how do you best marry a new radiation shielding structure with existing structures?

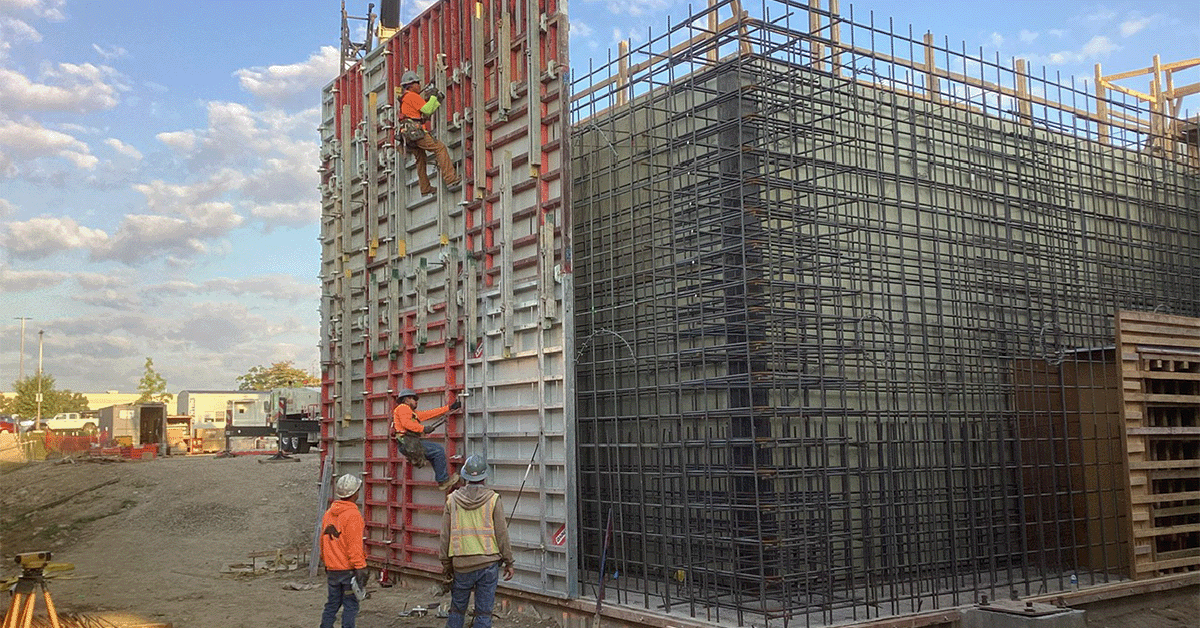

Incorporating Structural and Architectural Considerations

Integrating shielding solutions with the existing structural and architectural elements of a facility ensures a cohesive and efficient design.

In order to make the process as seamless as possible, make sure that your shielding designers, architects, and engineers all collaborate during every step of the project.

This is crucial to achieve effective integration that provides quality radiation protection.

Medical Radiation Shielding

Okay. We’ve talked about radiation shielding as a whole, the most popular materials, and how we effectively design proper shielding.

Now, it’s time to talk about the specific industries that we see utilize radiation shielding the most, starting with the medical field.

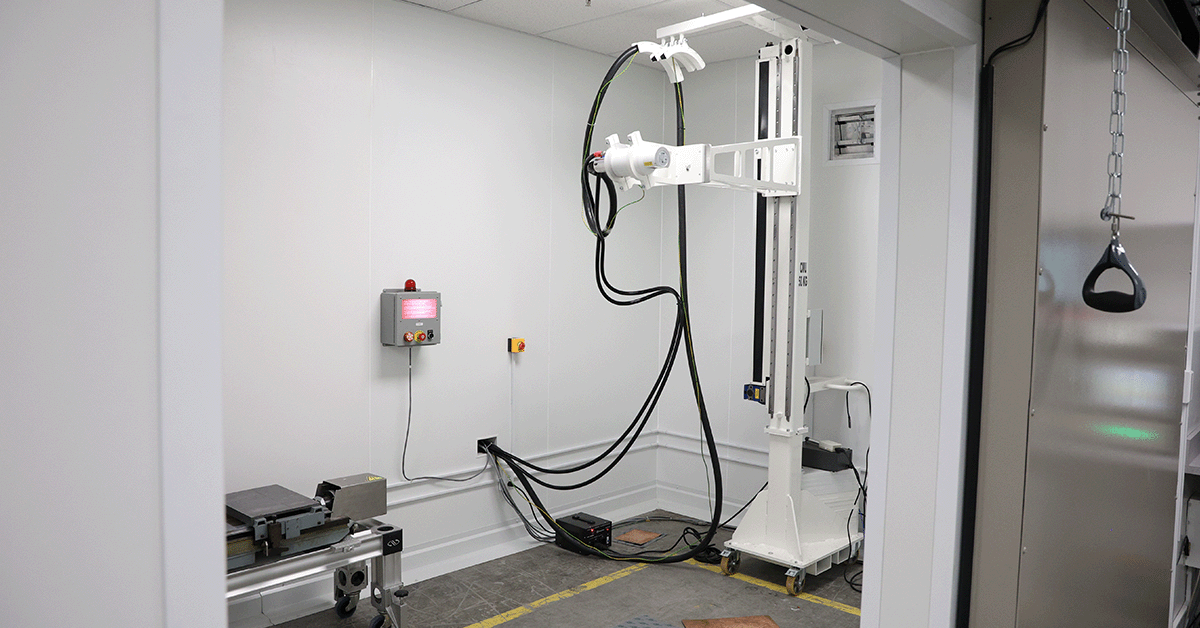

Medical Image Facility Radiation Shielding

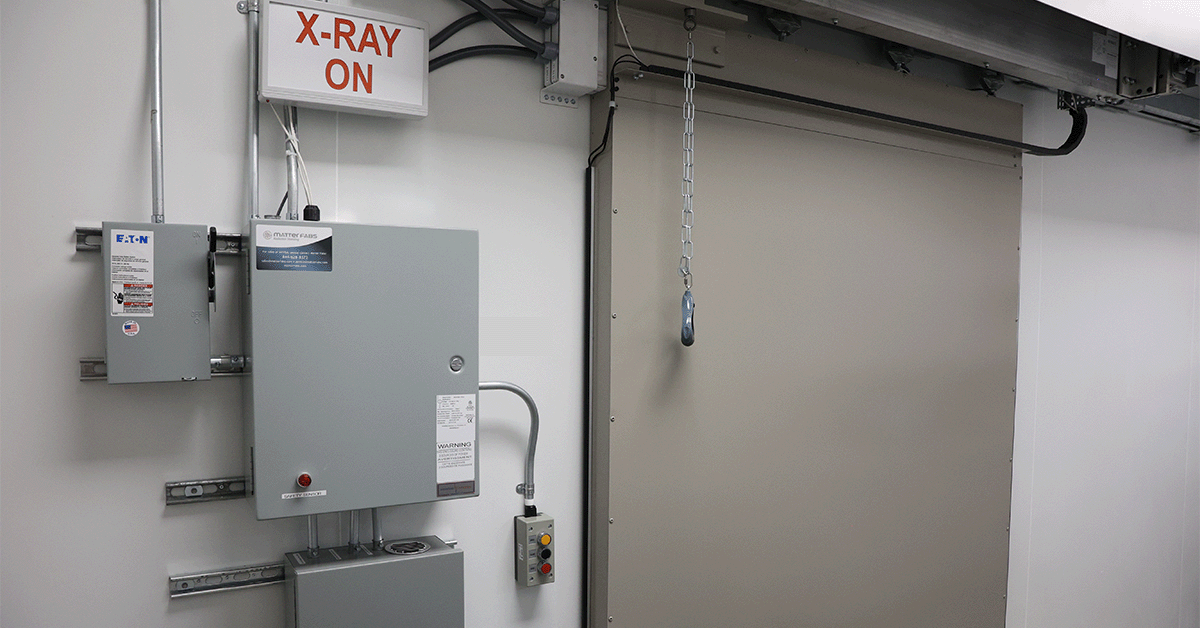

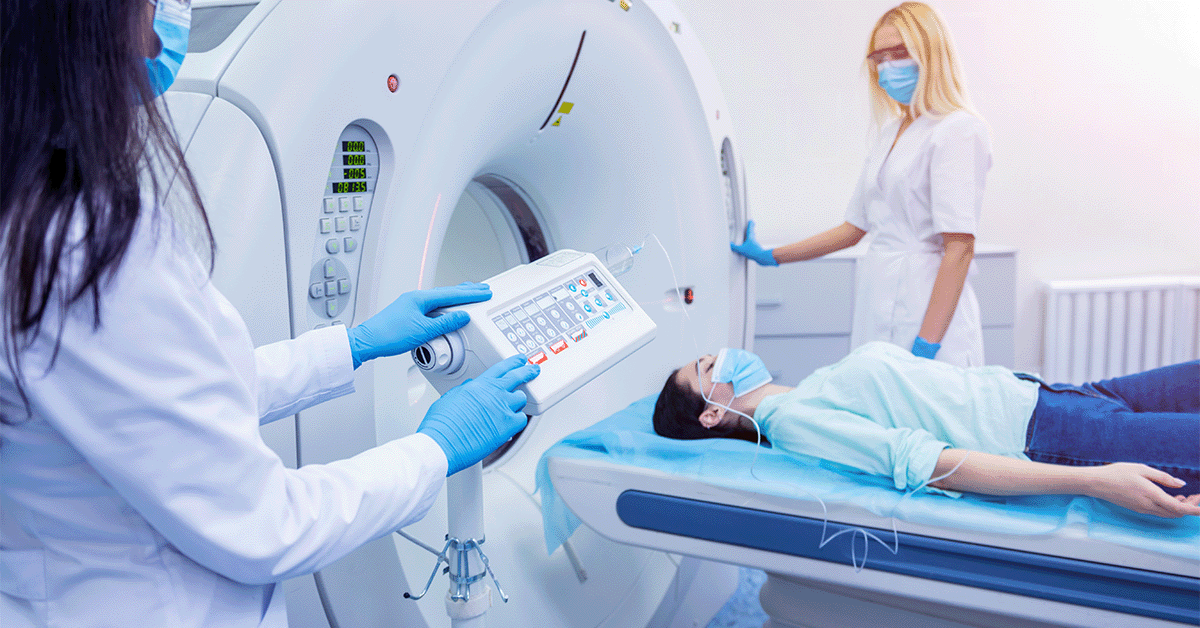

To kick things off, let’s talk about medical imaging facilities, such as X-ray and CT scan rooms.

You can find the use of medical imaging in every hospital and medical facility.

Unfortunately, these machines emit radiation during imaging, meaning they require radiation shielding to protect everyone in and around the room.

Shielding considerations for the medical imaging process include walls, radiation shielding doors, ceilings, floors and windows. In some cases, custom fabricated radiation shielding may be required for difficult areas.

Radiation Therapy Radiation Shielding

Just like medical imaging, some highly specified treatments require the use of radiation, commonly known as radiation therapy.

In fact, radiation treatment is commonly planned with information obtained from the imaging process.

As a result, radiation therapy facilities require advanced shielding. The amount of shielding required for treatment is much greater than just medical imaging.

For safety, shielding requirements include the treatment room and all areas around it.

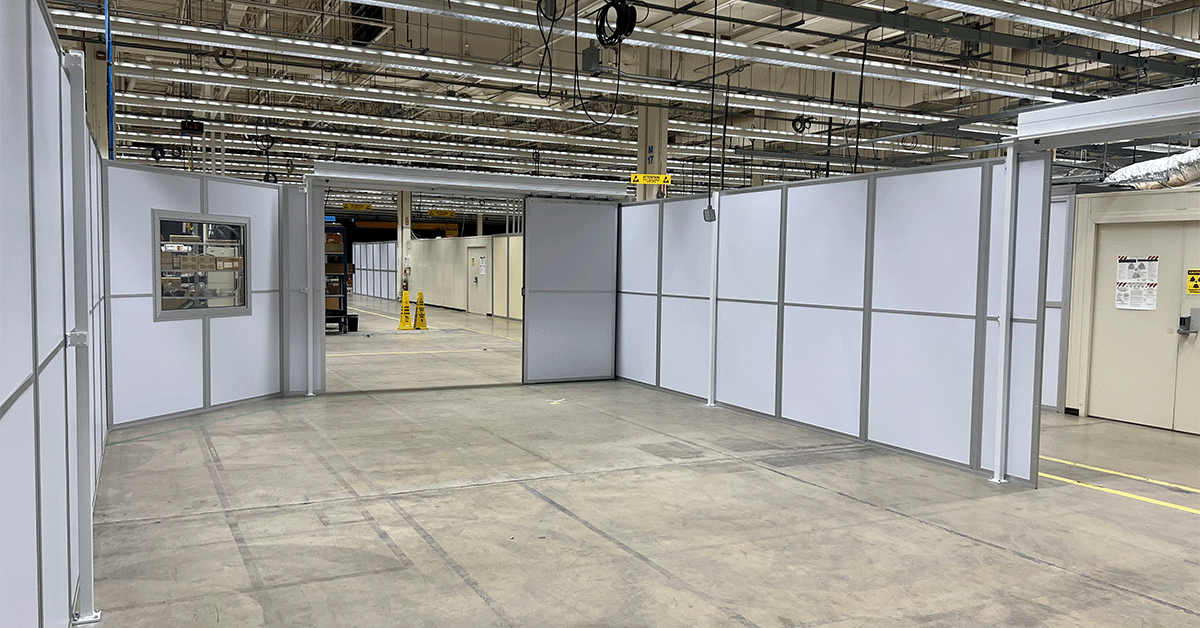

It’s important to note that temporary options exist for facilities who need to treat patients while they’re undergoing permanent facility construction or a machine upgrade.

Nuclear Medicine Radiation Shielding

With nuclear medicine, an even higher level of shielding is required due to the strength of the radiation that is being created.

This is due to the fact that nuclear medicine departments employ radioactive materials for diagnostic imaging and treatment.

Companies who employ nuclear medicine require shielding solutions that include hot labs and storage areas. These are non-negotiable to safeguard medical personnel and the public from radiation hazards.

Pet CT Radiation Shielding

Believe it or not, PET-CE and human CT practices are very similar in practice, and with the machines they use to conduct their work.

This means that just like the medical imaging we mentioned above, PET-CT and other advanced imaging modalities have specific shielding requirements due to higher radiation levels.

Design considerations for this type of radiation shielding involve integrating shielding with equipment, patient (Animal) positioning, and facility layout to optimize safety.

Industrial Radiation Shielding

Now that we’ve got into depth about some of the disciplines inside the medical industry that require radiation shielding to operate, it’s time to talk about the most common radiation shielding we build, industrial.

Industrial and research environments require effective radiation shielding measures to ensure the safety of personnel and prevent contamination. In the sections below, we’ll talk about nuclear power plants (the energy sector), industrial radiography non-destructive testing (RT for NDT), aerospace and defense, and the research and development discipline (R&D).

First up, NDT.

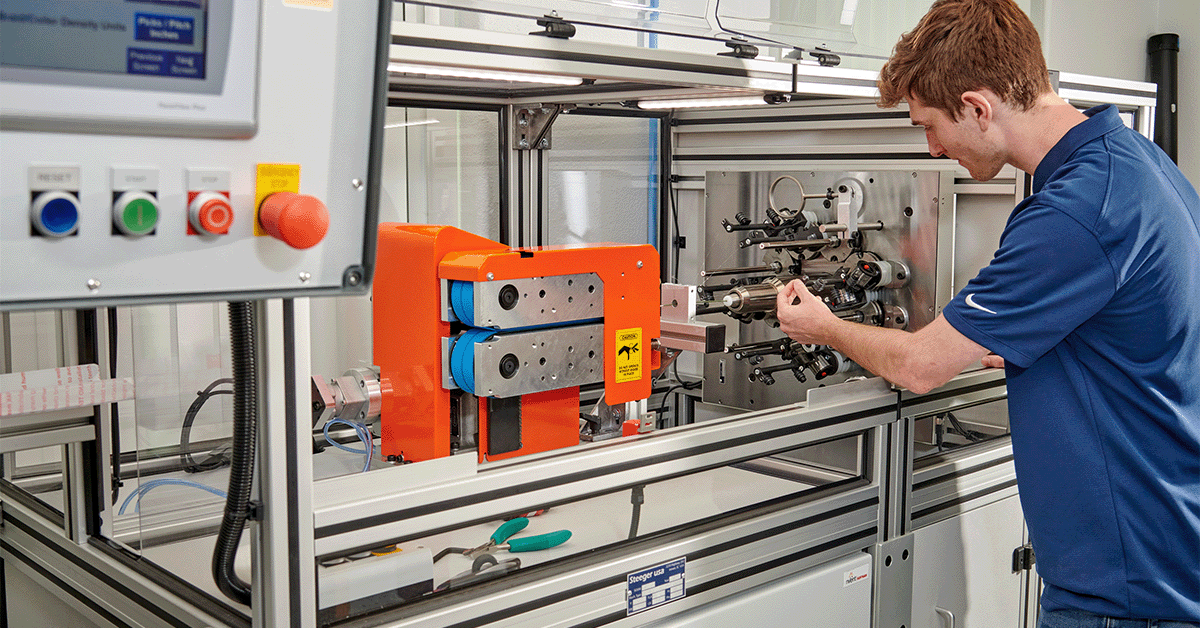

NDT Radiation Shielding

Okay, it’s time to talk about industrial radiography and non-destructive testing.

This is BY FAR where most of our clients do their work.

You might be asking – what is industrial radiography?

Well, RT involves the use of radioactive sources to inspect materials and structures.

Once film is in place, and proper distance is set, companies will place the product that’s being inspected inside the shielded room on a table or fixture, and activate the radiation source.

The radiation will reveal any defects in the product that can’t be seen by the naked eye. There are many other methods of NDT, but radiographic testing is the one we deal with.

Radiographic testing is a popular method because of how accurate it is. By using radiographic testing, you can save your company a lot of downtime, quality control issues, and possible added project losses.

You should check out our guide on all things NDT here.

Space Radiation Shielding

Spacecraft and satellites require shielding against cosmic radiation and solar flares during missions.

Lightweight yet effective shielding materials and designs are crucial to protect astronauts and sensitive equipment.

Aerospace Radiation Shielding

Radiation exposure is a concern for aviation crew and frequent flyers due to increased altitudes.

Shielding solutions involve cabin design considerations, such as reinforced structures and materials, to mitigate the potential health risks associated with cosmic radiation.

Naval Radiation Shielding

Let’s get out of the sky, and into the water.

It might surprise you, but nuclear-powered submarines and naval vessels require robust shielding to protect crew members from radiation hazards.

When you’re designing proper radiation shielding for the naval market, shielding considerations encompass the reactor compartment, control areas, and radiation containment measures.

Defense Radiation Shielding

Defense and military applications involving radioactive sources, such as nuclear weapons and materials, necessitate stringent radiation shielding measures.

Shielding solutions are designed to ensure the safety of personnel, minimize contamination risks, and protect sensitive equipment. Having high quality radiation shielding in place also allows this sector to protect what they’re working on from potential adversaries.

Speaking of protection, let’s talk about some best practices for radiation shielding safety and maintenance.

Radiation Shielding Safety

Ensuring radiation shielding safety involves implementing proper protocols, conducting regular inspections, and monitoring radiation levels in shielded environments.

Let’s discuss some of those protocols.

Radiation Safety Protocols and Training

Comprehensive radiation safety protocols and training programs are essential for personnel working in shielded environments.

Proper knowledge and understanding of radiation hazards and safety measures minimize the risks associated with radiation exposure.

Some of these protocols should include:

- Qualified staff (e.g., RSO, physicist) to provide oversight and responsibility for radiation protection policies and procedures.

- ALARA stands for As Low As Reasonably Achievable (ALARA). ALARA means avoiding exposure to radiation that does not have a direct benefit to you, even if the dose is small.

- A dosimetry program in which personal exposure monitoring is conducted, as required by federal or state regulations, for external dose and, as needed, for internal dose.

- Surveys and area monitoring to document radiation levels, contamination with radioactive materials, and potential worker exposures.

- Radiological controls, including entry and exit controls, receiving, inventory control, storage, and disposal.

- Worker training on radiation protection, including health effects associated with ionizing radiation dose, and radiation protection procedures and controls to minimize dose and prevent contamination.

- Emergency procedures to identify and respond to radiological emergency situations. (OSHA’s Radiation Emergency Preparedness and Response page also provides information about this topic).

- Record keeping and reporting programs to maintain all records and provide dosimetry reports and notifications, as required by federal or state regulations.

- Internal audit procedures to annually audit all aspects of the radiation protection program.

- It’s important to also note that more business-specific protocols may be necessary, and you should ask your RSO (Radiation Safety Office) for the details provided by your shielding company found in the manual received upon completion of the project.

Regular Inspections of Shielding Systems

Periodic inspections and maintenance of shielding systems help identify potential issues and ensure their continued effectiveness.

These inspections include (but are not limited to):

- Regular checks of shielding integrity

- Consistent structural integrity testing

- Radiation leakage scans

Just like protocols, these will vary, and need to be fully understood before operating the radiation-emitting machine or sources.

Compliance with Regulatory Requirements and Periodic Audits

Adhering to regulatory requirements and undergoing periodic audits from a number of agencies is essential to ensure compliance and demonstrate the effectiveness of radiation shielding measures and keep your business up and running legally.

Compliance with standards ensures the highest level of safety and minimizes potential liabilities.

Emerging Radiation Shielding Technologies

Just like any other industry, scientists and engineers are hard at work advancing the radiation shielding industry.

Rapid advancements in technology bring forth new tools, materials, and approaches that enhance radiation shielding effectiveness and efficiency, while being more budget friendly.

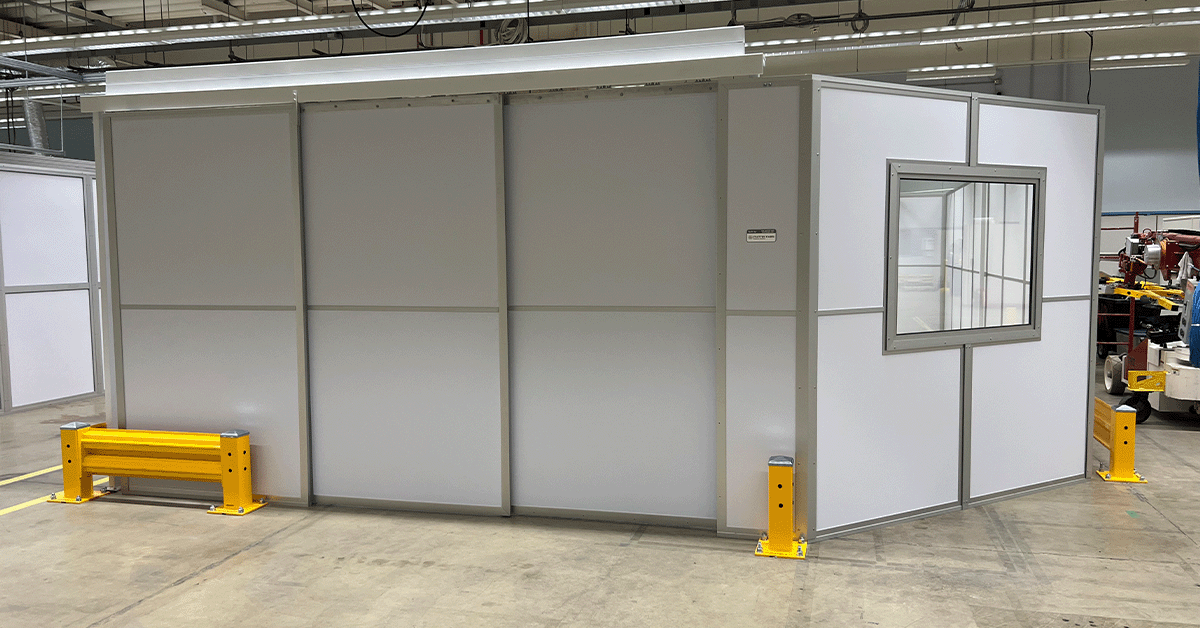

In fact, we’re really proud to have some innovations of our own, like our low-level radiation panel system.

Radiation Detection and Monitoring Devices

New radiation detection and monitoring devices offer improved accuracy, portability, and data collection capabilities.

These technologies aid in precise measurement and monitoring of radiation levels, enhancing safety protocols and risk management.

Novel Materials

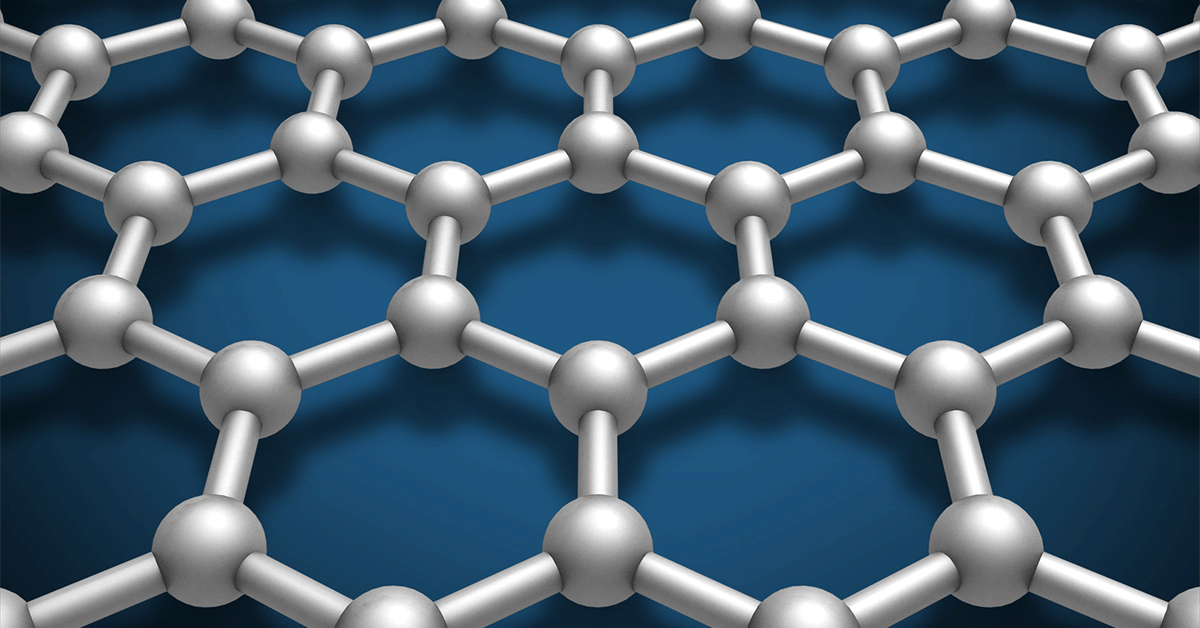

Researchers and engineers continue to develop novel materials and technologies for radiation shielding.

Innovations such as nanocomposites, metamaterials, and lightweight alloys show promise in improving shielding efficiency and reducing the overall weight and cost of shielding systems.

There is also a lot of experimentation with different types of aggregates used in concrete to increase density, effectively reducing the amount required.

Digital Modeling and Simulation Tools

Advanced digital modeling and simulation tools enable the optimization of shielding designs for specific applications.

These tools allow for accurate predictions of shielding effectiveness, helping designers create efficient and cost-effective shielding solutions.

Before We Close

Thank you for reading this article! As we mentioned before, this will serve as an ever-green piece of content that will be updated regularly with the most up-to-date and accurate information available. We have confidence in our abilities as the industry leader in radiation shielding, and we hope that’s apparent through this information.

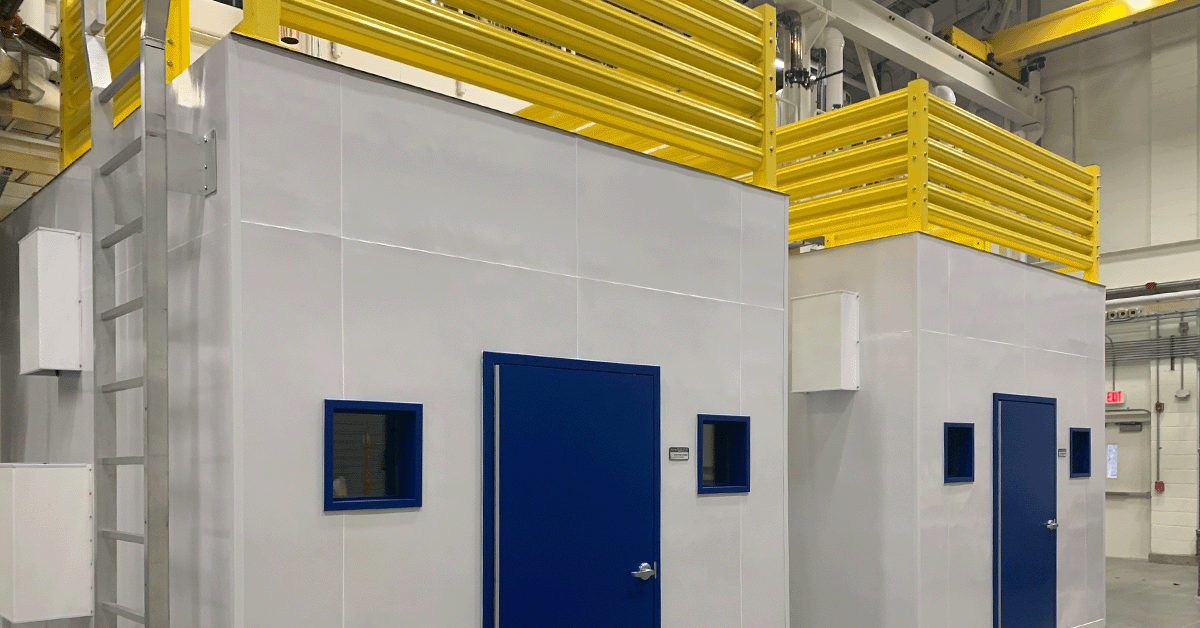

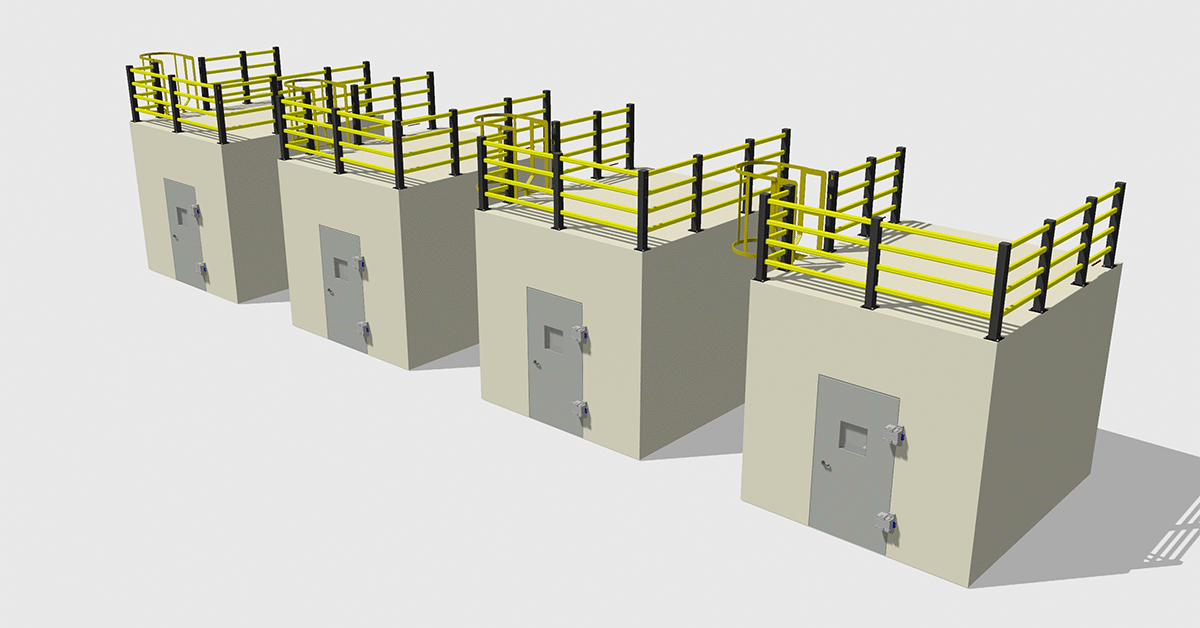

If you’re interested in building high-quality, cost-effective radiation shielding, contact us. We’ve got 30+ years of experience delivering the best shielding in the marketplace. In fact, our patented MatterVault is one of the many innovations our team prides itself on.

Check out this blog explaining the Mattervault in more depth.

Okay, enough talking about us, let’s finish the blog.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of the shielding industry with our weekly e-newsletter.

Conclusion

In conclusion, radiation shielding is of utmost importance in various industries and applications to protect against the potential hazards of radiation exposure.

We hope that this comprehensive guide has provided valuable insights, best practices, and expert knowledge to enable the implementation of effective radiation shielding solutions.

Recap of Key Points

Throughout this guide, we have covered the fundamentals of radiation, the different types of radiation shielding materials, and the design considerations for effective shielding solutions.

We explored radiation shielding in medical, industrial, and aerospace applications, discussed safety protocols and maintenance, and highlighted emerging technologies in the field.

The Importance of Proper Radiation Shielding

Proper radiation shielding is crucial for ensuring safety, protecting personnel, and minimizing the risks associated with radiation exposure.

By implementing effective shielding solutions, industries can create safer environments for their workers and enhance overall radiation protection.

Applying Insights and Best Practices

We encourage readers to apply the insights and best practices shared in this guide to their respective industries and applications. If you don’t put into practice what you read, what was the point?

By prioritizing radiation shielding and following the recommended guidelines, organizations can achieve optimal safety and mitigate the potential hazards of radiation exposure.

Implementing effective radiation shielding requires careful consideration of radiation types, shielding materials, design parameters, and regulatory compliance.

Collaboration with radiation safety experts and professionals is crucial for optimal results. With the rapid advancements in technology and ongoing research, the future of radiation shielding holds great promise for improved safety and innovative solutions.

By understanding the importance of radiation shielding and incorporating the best practices outlined in this guide, industries can create safer working environments, protect personnel, and mitigate the risks associated with radiation exposure.