*This post is a pillar post for insulated metal panels (IMPs). Multiple in-depth blog posts have been linked throughout this article for more information on specific topics.

Table of Contents

ToggleIntroduction

Insulated metal panels (IMPs) are a revolutionary construction material that combines a metal exterior and interior face with a foam or mineral wool core.

These panels offer superior thermal insulation, structural support, and aesthetic appeal for a wide range of building applications. IMPs have gained significant traction in the construction industry due to their numerous advantages, including energy efficiency, durability, and design flexibility.

They have become a preferred choice for architects, builders, and property owners seeking high performance building envelopes. In this comprehensive guide, we’ll provide a thorough understanding of insulated metal panels, their benefits, applications, installation process, and comparisons with other building materials.

By the end of this guide, you will have the necessary knowledge to make informed decisions regarding the implementation of IMPs in their construction projects. To start, let’s go a bit deeper into what IMPs are, and how they work.

Understanding Insulated Metal Panels

In this first section, we’ll be discussing the components and structure that make up an insulated metal panel, the different types of IMPs that exist, key features of IMPs that make them so great, and the most common applications they’d be used in.

This section will set the stage for the rest of the article, and will provide helpful foundational information.

Components and Structure of IMPs

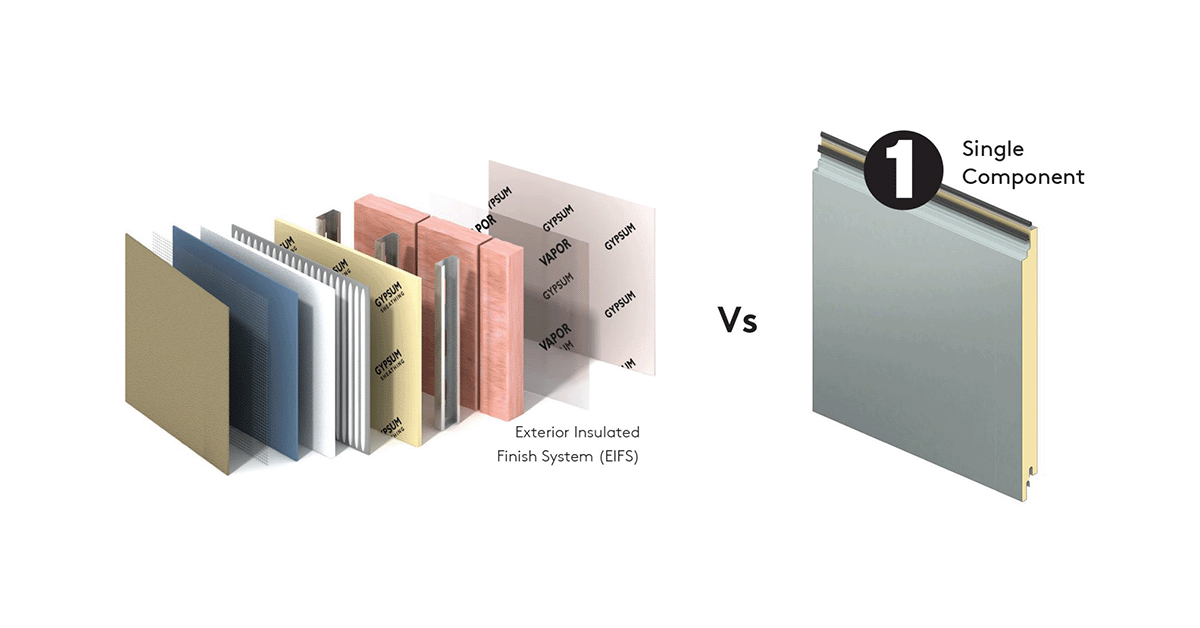

IMPs typically consist of an exterior metal face, an interior metal face, and a foam or mineral wool core.

These components work together to provide insulation, structural support, and protection against external elements.

If you’re more of a visual person, the image below might help.

Key Features and Benefits of Insulated Metal Panels

IMPs offer a wide range of benefits, such as superior thermal performance, weather resistance, fire safety, noise reduction, and sustainability.

They contribute to energy savings, occupant comfort, and reduced environmental impact.

There’s a reason why they’ve become extremely popular for commercial builds. We’ll go much more in-depth in the next section regarding this topic.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of the construction industry with our weekly e-newsletter.

Insulated Metal Panel Applications

IMPs are widely used in commercial, industrial, and residential buildings. They are suitable for applications such as exterior walls, roofs, cold storage facilities, cleanrooms, agricultural buildings, and more.

For example, we constructed a research facility for LG with insulated metal panels.

Advantages of Insulated Metal Panels

Before you read about the great benefits of insulated metal panels, check out this video by one of our foremen, Nathan Cymbal.

Energy Efficiency and Thermal Performance

Insulated metal panels provide exceptional thermal insulation, reducing heating and cooling costs and enhancing energy efficiency.

They minimize thermal bridging and create a continuous insulation envelope.

Enhanced Building Envelope and Weather Resistance

With their airtight construction, IMPs create a superior building envelope, preventing air infiltration and moisture ingress.

They offer excellent resistance to wind, rain, and extreme weather conditions.

Fire Resistance and Safety

IMPs with mineral wool cores offer exceptional fire resistance and meet stringent fire safety regulations. They contribute to creating safer buildings and protecting occupants and property.

Noise Reduction and Acoustic Properties

The sandwich-like structure of IMPs, combined with the inherent sound-absorbing properties of their core materials, helps reduce noise transmission, improving acoustic comfort within buildings.

Sustainability and Environmental Benefits

IMPs are environmentally friendly, as they often contain recycled content and can be recycled at the end of their life cycle. They contribute to energy-efficient buildings and can help achieve green building certifications.

Cost-Effectiveness and Long-Term Savings

Although the initial cost of IMPs may be higher than some traditional materials, their long-term benefits, including reduced energy consumption, maintenance costs, and extended lifespan, result in substantial savings over time, boosting your ROI tremendously.

Considerations for Designing with Insulated Metal Panels

So, by this point you might have decided to choose IMP panels for your next project. Well, what are some of the most important things to consider before finalizing your decision?

Factors to Consider During the Design Phase

Designers should consider factors such as panel dimensions, insulation thickness, attachment methods, and compatibility with other building systems when incorporating IMPs into the project.

Integration with Other Building Systems and Components

Proper coordination with other building systems, such as HVAC, electrical, and plumbing, is crucial to ensure seamless integration and optimal performance of IMPs within the overall building design.

Customization Options and Design Flexibility

IMPs offer a wide range of customization options, being available in a variety of attractive finishes, including smooth, textured, embossed, and metallic coatings as well as a number of color options.

These finishes enhance the visual appeal of buildings, providing versatility in design choices.

This allows architects and designers to achieve their desired aesthetics while maintaining the functional benefits of IMPs.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of the construction industry with our weekly e-newsletter.

Compliance with Building Codes and Regulations

When using IMPs, it is essential to ensure compliance with local building codes and regulations.

Manufacturers and suppliers can provide guidance and documentation to assist in meeting these requirements. As the sub-contractor who installs these panels, your GC will work closely with these entities to guarantee compliance.

Case Studies and Examples

Several real-life case studies demonstrate the successful implementation of IMPs across various sectors, including commercial, industrial, educational, and healthcare facilities. These examples highlight the benefits and outcomes achieved through IMP usage.

What Buildings Use Insulated Metal Panels?

What are the most common sectors of the economy that utilize IMPs?

Insulated metal panels are used in a variety of applications, including retail, warehouses, automotive facilities, sports complexes, schools, and hospitals.

Their versatility and performance helps them fit different industries, and makes them suitable for both new construction and retrofit projects.

Comparing Insulated Metal Panels to Other Building Materials

When using a new building material for the first time, it’s extremely important to thoroughly compare it to typical tried and true construction material staples.

Insulated Metal Panels vs Traditional Building Materials

When you compare insulated metal panels to traditional construction materials such as wood, steel, and concrete, it’s not even close.

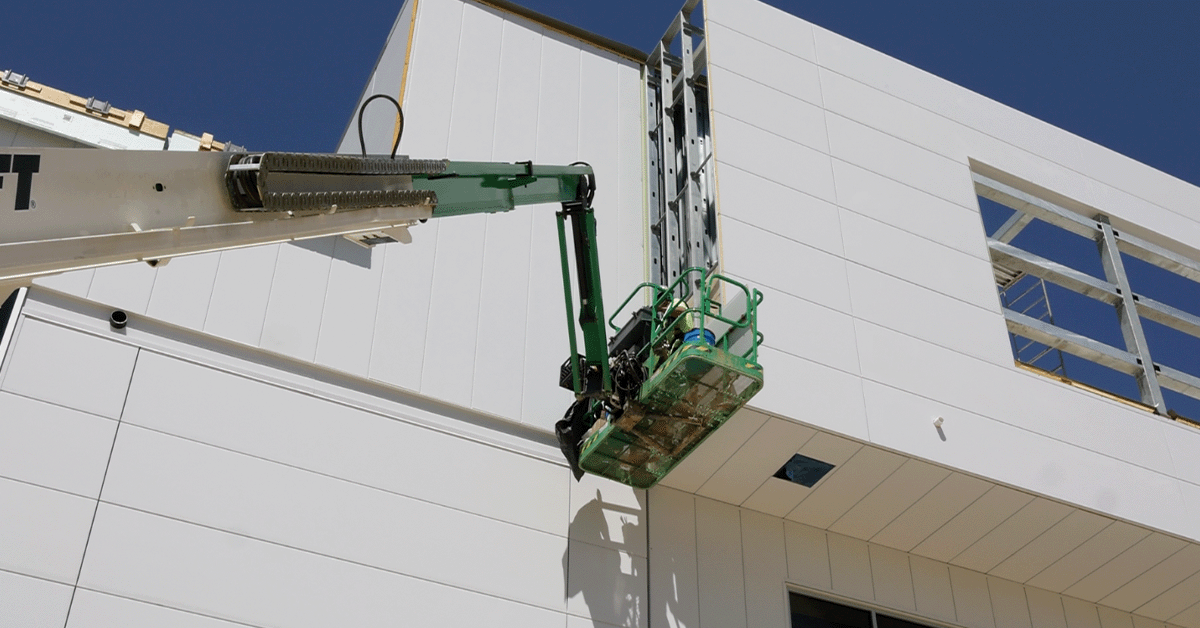

IMPs have the leg up in almost every situation with advantages such as superior insulation, faster installation, reduced labor costs, enhanced durability, and sustainability benefits. They’re affordable, fast, and high-quality. Full stop.

Advantages and Disadvantages of IMPs

Although IMPs outperform traditional materials in terms of energy efficiency, thermal performance, weather resistance, and fire safety, there are a few things to be aware of.

Considerations such as initial cost, architectural design limitations, and specialized installation techniques should also be taken into account before using them.

Cost, Performance and Sustainability

Like we mentioned briefly, IMPs may have a higher initial cost compared to some traditional materials, but their long-term benefits, such as energy savings and reduced maintenance, often offset the higher upfront investment.

Insulated Metal Panels’ environmental benefits, recyclability, and potential for achieving green building certifications also make them an attractive choice for sustainable construction.

Future Trends and Innovations

As with any industry, construction materials are always evolving. Let’s look at some of the key ways insulated metal panels continue to innovate.

Emerging Technologies and Advancements in IMPs

Ongoing research and development in IMPs are focused on improving their thermal performance, fire resistance, structural capabilities, and installation efficiency. New technologies, such as advanced coatings and insulation materials, are being explored for widespread commercial use.

Potential Improvements to Insulated Metal Panels

Further advancements may include increased insulation values, integration of smart building technologies, and enhanced customization options.

Research efforts also aim to optimize IMPs’ sustainability and recyclability.

Impact of IMPs on the Future of Construction

IMPs are poised to play a significant role in the future of construction, driven by their energy efficiency, sustainability, and design flexibility.

Their adoption is expected to increase as more architects, builders, and property owners recognize their benefits and move away from more traditional methods of construction.

Conclusion

We hope that this guide has provided a comprehensive understanding of insulated metal panels, including their components, benefits, applications, installation process, comparisons with other materials, and future trends.

Insulated metal panels have revolutionized the construction industry, offering a holistic solution for energy-efficient, durable, and aesthetically pleasing buildings.

Their versatility and performance make them a valuable choice for a wide range of construction projects.

As the construction industry continues to prioritize energy efficiency, sustainability, and performance, exploring and implementing insulated metal panels can lead to significant benefits for your business.