*This post is part of a much larger pillar blog: The Ultimate Radiation Shielding Guide

Table of Contents

ToggleIntroduction

Radiation shielding is a critical aspect of modern industries, ensuring the safety of workers, equipment, and the environment in applications involving harmful radiation.

With the rapid advancement of technology, digital modeling has transformed the field of radiation shielding. Once all necessary data is compiled, digital modeling allows engineers to work with speed and accuracy.

This article explores the intricate world of digital modeling for radiation shielding, uncovering its significance, techniques, and future prospects.

Let’s begin.

The Evolution of Radiation Shielding

It might seem redundant, but it’s important for us to go over some basic radiation shielding principals, just in case you’re not fully up to speed.

Industries such as healthcare, nuclear power, aerospace, and manufacturing heavily rely on radiation for various applications. Radiation allows hospitals to conduct x-rays, nuclear plants to produce energy, and manufacturing operations conduct important quality control measures.

However, radiation can pose significant health risks. Radiation shielding mitigates these risks by using materials to absorb or scatter radiation, safeguarding human health.

Let’s talk a little bit about where the methodology of digital modeling came from.

Radiation Shielding Techniques

Now you might be asking yourself, what are some of the specific advancements that have been made over the years?

Well, although the materials used for radiation shielding may not have changed (lead, tungsten, steel, concrete, sand and many more), the tools which radiation shielding professionals (such as ourselves) use to design and construct these structures have greatly improved.

Here’s how.

The Role of Digital Modeling in Radiation Shielding

In this section, we’ll give a quick introduction into what exactly digital modeling is and discuss what some of the advantages are.

Digital Modeling and Simulations

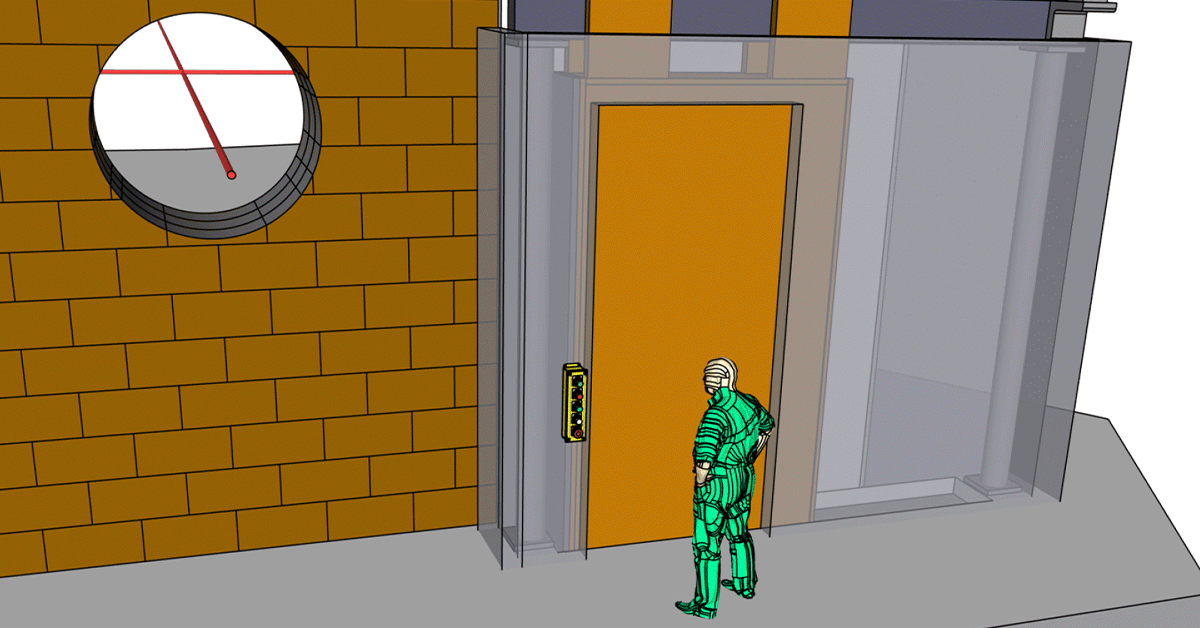

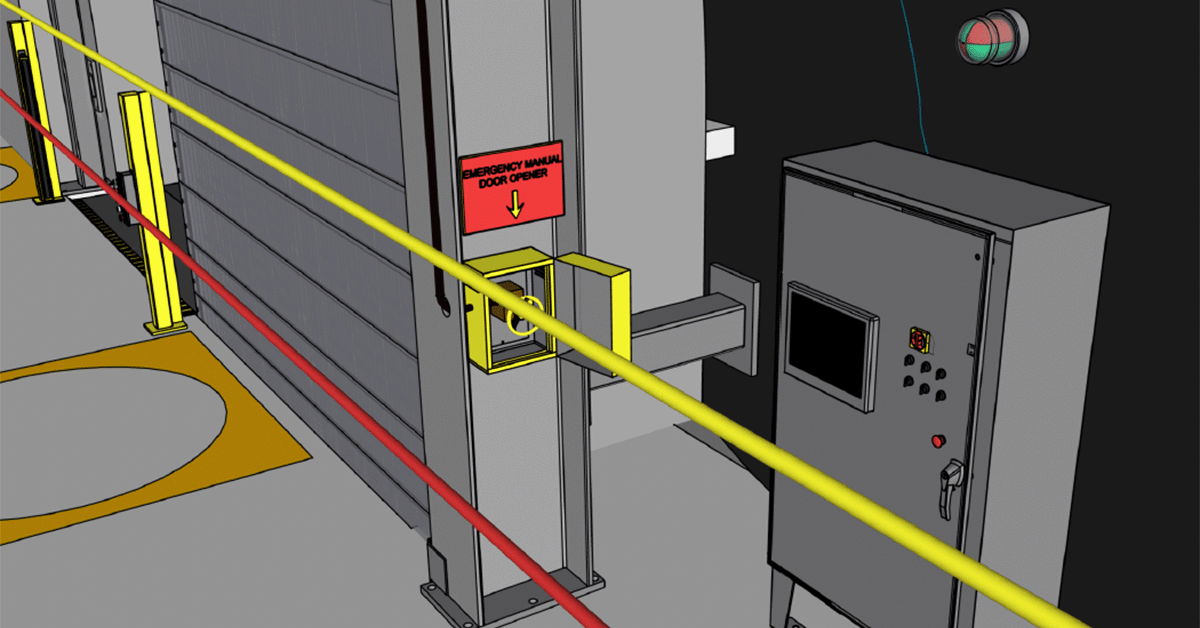

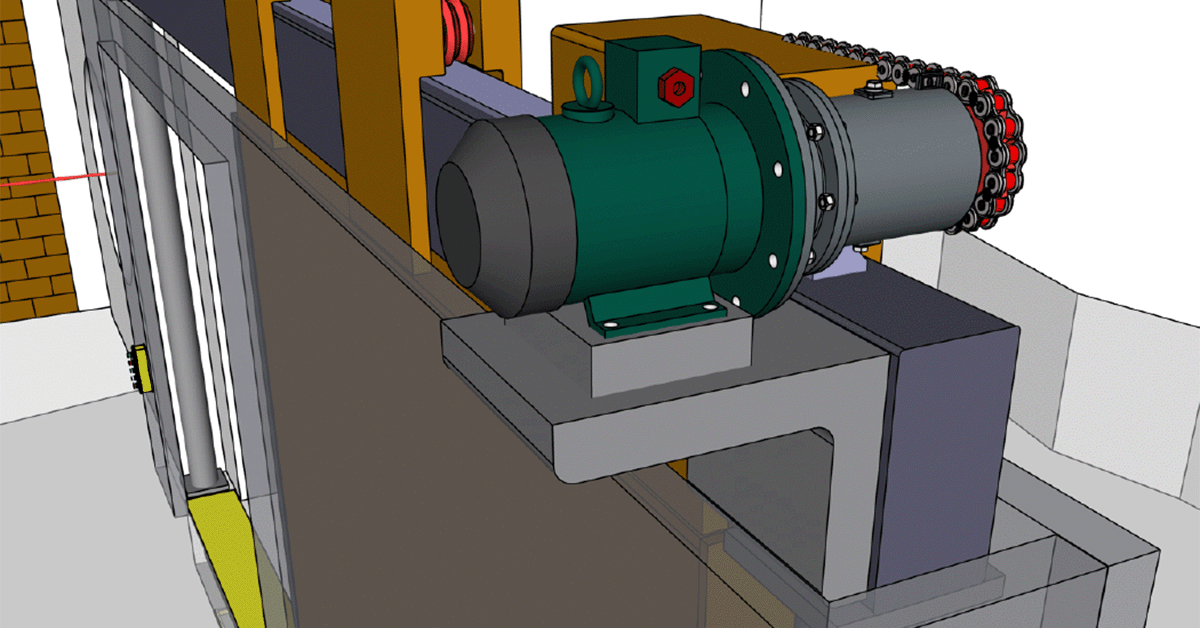

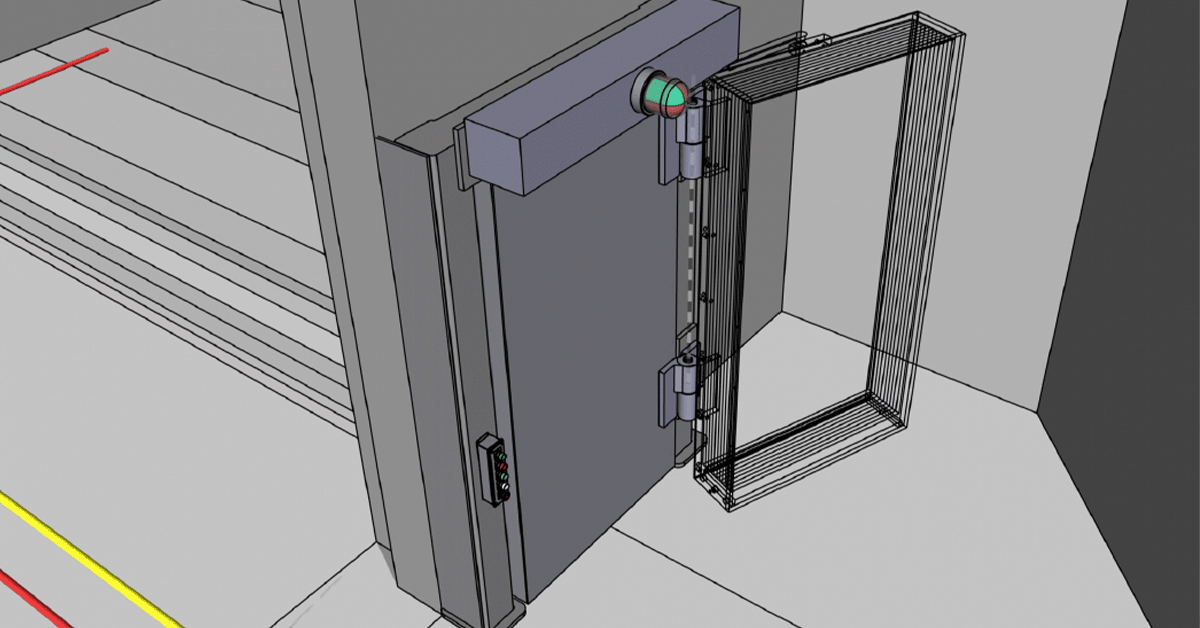

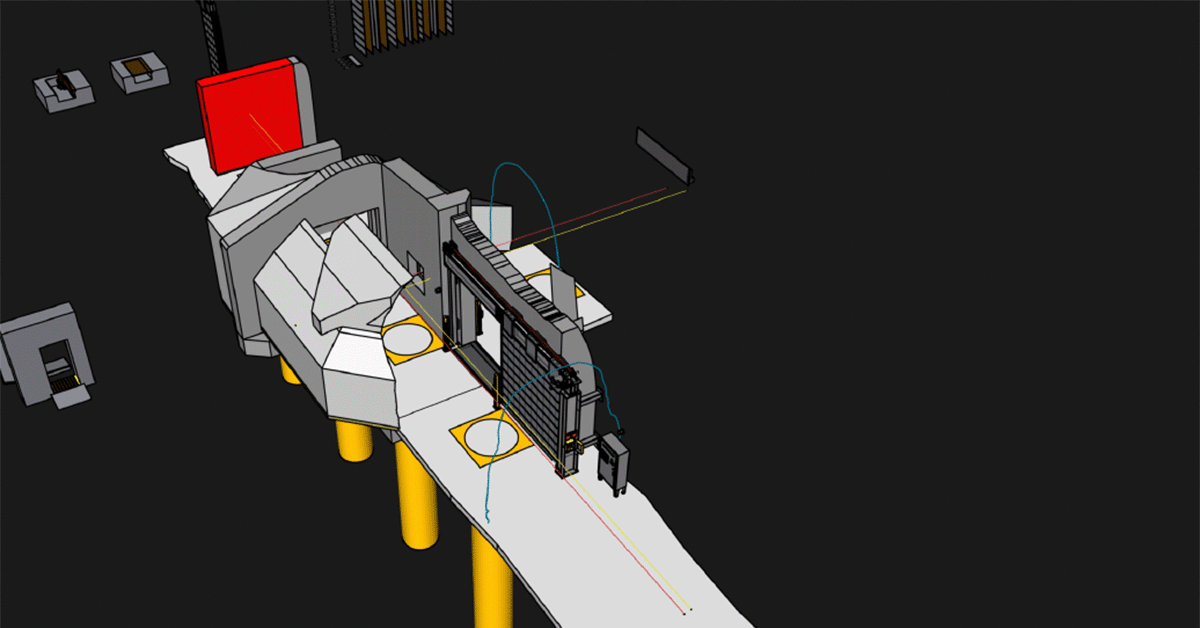

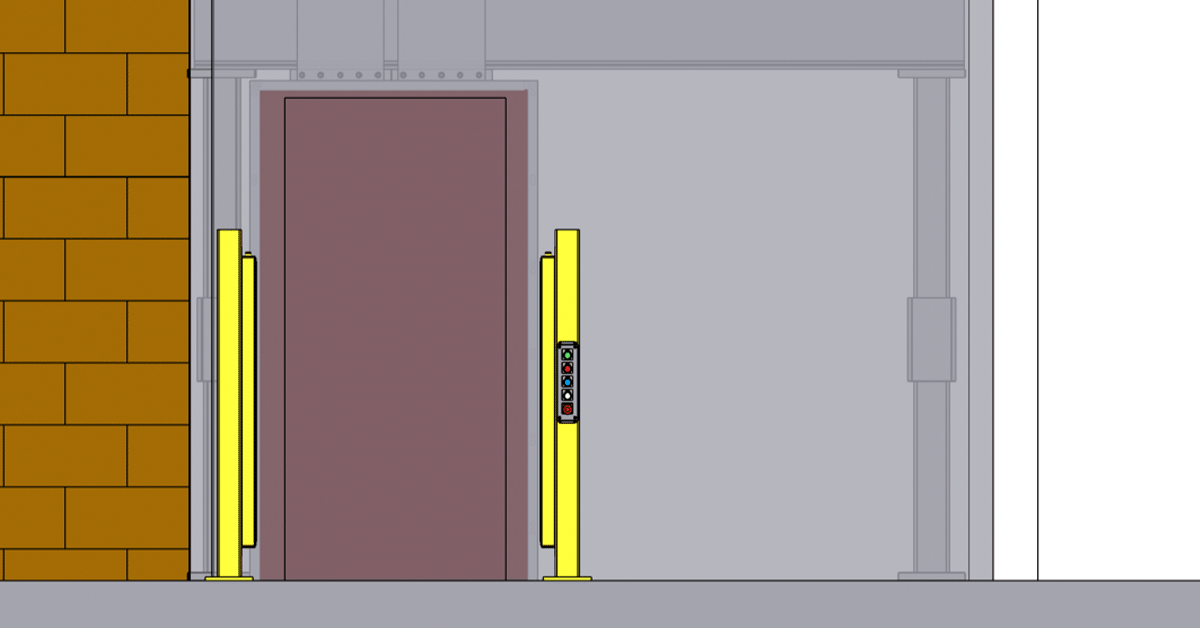

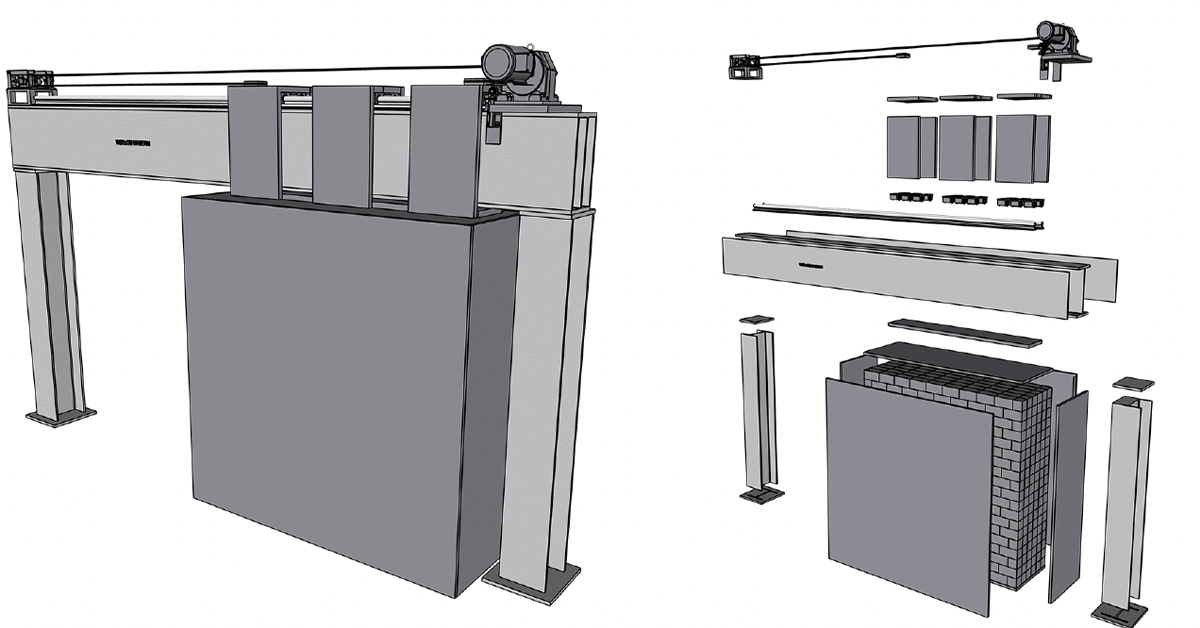

Digital modeling, also known as digital rendering, employs computer simulations to accurately show our customers shielding requirements and expectations. This really helps our customer to understand our quote, and explains exactly what the final construction will look like.

It is by far one of the best ways for us to communicate expectations with our customers to guarantee they’re getting exactly what they want.

These models also allow physicists to have a tool to determine what’s needed to accurately determine the shielding requirements via shielding study.

Ultimately, these models make understanding the shielding structure extremely easy.

The Advantages of using Digital Modeling

Digital modeling offers rapid design development. When you’re constructing a radiation shielding structure, modeling saves time and resources during the research and development stage.

Additionally, it allows for the exploration of different scenarios in a controlled environment that may provide an alternative solution for the client that they may not be considering, or even aware of.

Types of Digital Modeling Techniques

Now that we’ve explained in depth the role of digital modeling, let’s take a closer look at the specific methods our team (and many others) use.

Monte Carlo Simulations: Working Principle and Applications

The first modeling solution we’ll look at is arguably also the most common. The Monte Carlo Technique.

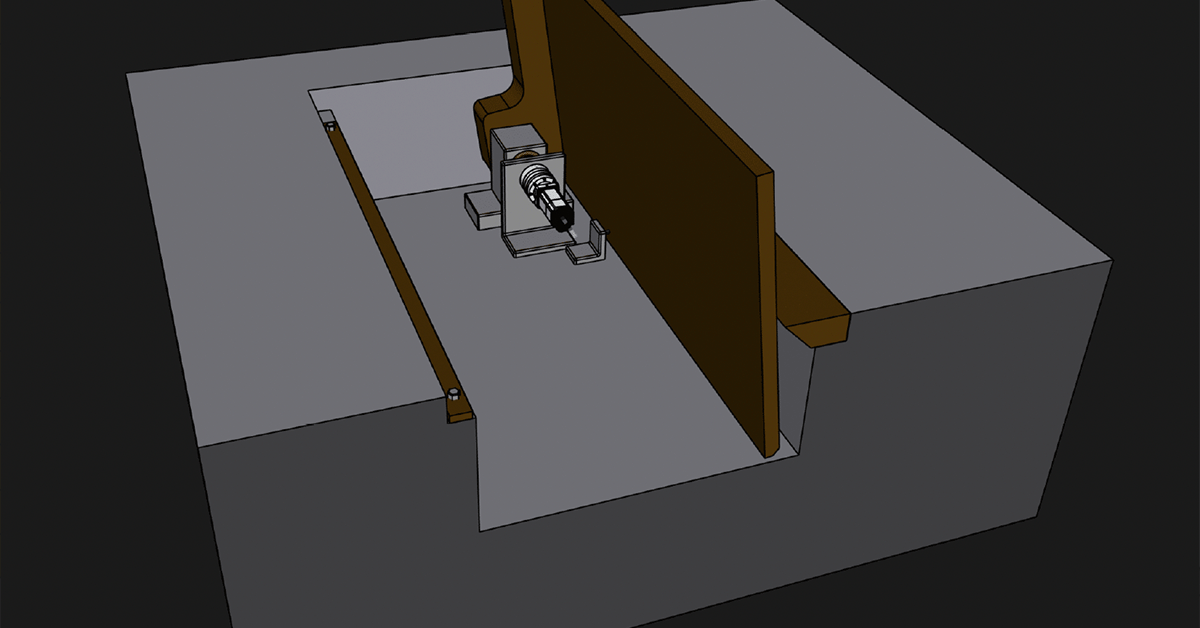

Monte Carlo simulations trace the paths of individual radiation particles, providing precise calculations of radiation behavior.

This technique is particularly useful for intricate scenarios and complex geometries that are usually time intensive to calculate by hand.

Finite Element Analysis for Radiation Shielding Design

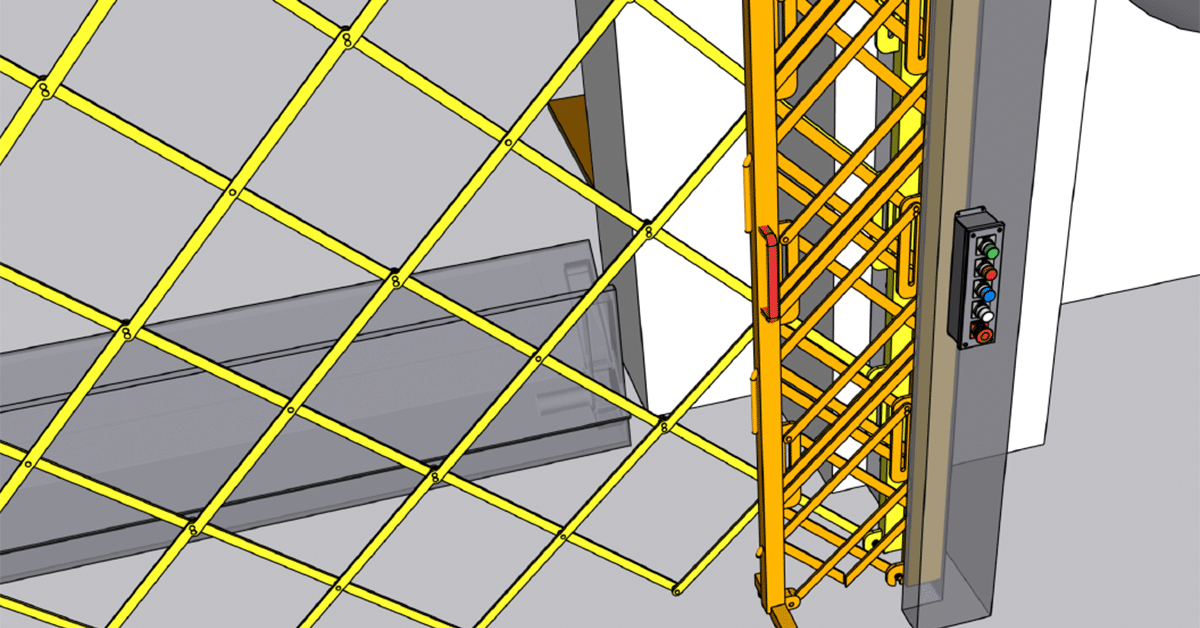

Finite Element Analysis (FEA), the second most popular digital modeling technique, simulates the behavior of structures under various conditions.

For radiation shielding, it can predict stress distribution, radiation attenuation, and overall shielding performance. This is particularly great for operations that have a large dose being emitted.

Developing a Digital Radiation Shielding Model

With a good understanding of the most common (and effective) digital modeling techniques, we’re going to walk you through our in-house process for developing a comprehensive digital radiation shielding model.

Collecting Data and Parameters for Model Development

Accurate data collection, the first step, including radiation source characteristics, material properties, and geometry, is essential for model accuracy. This needs to be done off the bat to allow the engineers to have a database to work from.

The most important aspect of data is how you use it.

Choosing the Right Software for Digital Modeling

Specialized software tailored for radiation shielding simulations provides the necessary tools and algorithms for precise modeling.

Choosing the right software comes down to the specific needs of your business, your budget, and personal preference.

Steps in Building a Comprehensive Shielding Model

The following is a basic outline of how we build our models. However, please note that each project is different, and may require adjustments to the typical process.

The Discovery Stage

Each project starts with gathering information from the customer. We want to know what they’re looking for, and what their expectations are for their final shielded structure. Our team uses our in-house discovery questionnaire to gather information on the source inside the room, what they’ll be using it for, occupancy factors, and more.

Preliminary Model Construction

After our potential client fills out the questionnaire, our design team creates a preliminary model based on our very rough shielding estimates. We can’t do a 100% accurate model without physics done, which occurs after the PO is submitted.

Client Revisions

Now that our first model is done, we meet with the client and walk through what we’ve designed. Our design includes how the machines look inside, and even some environmental factors such as parking lots.

Quoting the Project

After the client approves the rendering, our team provides them with a rock-solid quote. Then, we receive a P.O. and start the job.

Rendering Hand-Off

At the outset of the job, we review the model one last time, and then transfer it to our engineer to make detailed breakouts of the design.

Final Design Process

At AVM Group, we follow something we call “30/60/90/100”. Here’s exactly what that means:

30%

At the 30% completion percentage point, the concept design is completed. This concept design defines the major design elements of the project, and helps the refine the project scope.

60%

The 60% completion point is a huge milestone. This is the point where we review the current design, and compare it to the concept design. We want to make sure the project can be constructed, and that the specifications will meet the objectives of the project without significant design changes.This is also where we finalize any new expectations from the client, and provide the current design information.

This includes things like system weights, loads, overall sizes, and any special application needs and power requirements. Also, we will check the current design to the original SOW and budget for any added cost and timing that needs to be addressed.

90%

As we begin to round the corner towards the end, we hit the 90% mark. At this point, the design is complete, and all requirements are met.We then meet with the customer to review and confirm the design intent. All final third party audits are performed if required, and confirmation on deliverables for key components of the design occur.

100%

It’s time to close out the design. At this stage, the design is ready for the 100% sign-off/approval by the customer to release the model for build construction.

Finally, manufacturing build prints/detailing prints are started after the customer approval.

Future Trends in Digital Modeling

It’s always best practice to be on the lookout for changes in the industry that could have a huge impact on the work your company outputs.

Integration of Artificial Intelligence in Shielding Simulations

AI enhances predictive accuracy and suggests optimal configurations, improving shielding designs. AI has been quite the hot topic recently, and for good reason. By using complex algorithms, you can make the mental strain of difficult calculations easier.

Advancements in High-Performance Computing for Complex Models

Increased computational power allows for more detailed and accurate simulations. Computing continues to advance so rapidly that it’s hard to keep up. These machines will only get stronger, faster, and cheaper, which is good news for those who develop digital models.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of the shielding industry with our weekly e-newsletter.

Conclusion

In conclusion, digital modeling has revolutionized radiation shielding, allowing for precise design, accurate predictions, and rapid iteration.

As technology evolves, the synergy between digital modeling and radiation shielding promises to enhance safety across industries, ensuring a radiation-protected future.

Need a digital model of your next shielding structure done? Contact us.