*This post is part of a much larger pillar blog: The Complete Guide to Controlled Environments

Introduction

In today’s rapidly evolving world, controlled environments play a critical role in various industries, ranging from pharmaceuticals and biotechnology to electronics manufacturing and research laboratories.

That’s why avoiding common controlled environment challenges is crucial for achieving consistent and reliable outcomes.

In this article, we will explore the most common challenges faced in controlled environments and discuss effective strategies to avoid or overcome them.

What is a Controlled Environment?

Before we begin, it’s important to lay some basic ground work for how a controlled environment is defined.

Controlled environments are characterized by tightly regulated parameters such as temperature, humidity, pressure, and cleanliness.

These rooms are integral to industries that demand precise and consistent outcomes, such as semiconductor and lithium ion battery production, research and development, and food processing, where even minor deviations can lead to significant financial losses and compromised results.

Alright, with that out of the way, let’s talk about the most common controlled environment challenges we see.

The Most Common Controlled Environment Challenges

Given that controlled environments have so many components, there are many possible points of failure.

In the following paragraphs, we’ll cover common controlled environment challenges such as temperature and humidity, contamination, equipment issues, and more.

If you want to learn how to resolve them, make sure to read the section following this one.

[elementor-template id=”3105″]

Temperature and Humidity Fluctuations

To start things off, let’s discuss the most common controlled environment challenge, regulation of temperature and humidity.

Fluctuations can disrupt delicate processes and cause variations in results, leading to decreased product quality and research reliability. Dynamic equipment loads and changing outdoor air conditions can all produce temperature and humidity fluctuations.

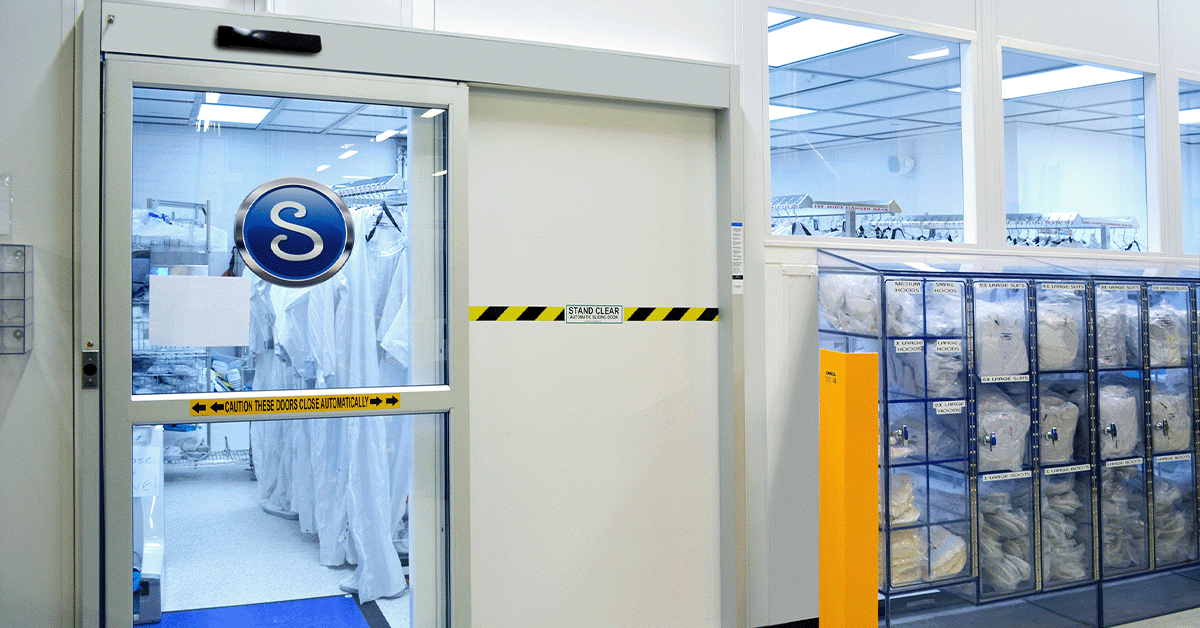

Contamination Control

The next issue we see is contamination control.

Without a doubt, preventing contamination is a constant battle.

Airborne particles, microorganisms, and other contaminants can infiltrate controlled environments through issues with crucial entry point seals, improper gowning procedures, and a number of other bad practices.

Contamination will easily jeopardize experiments and production processes.

Equipment Malfunctioning

The next controlled environment challenge we’ll talk about is something you (for the most part) have no control over, equipment failure.

Equipment failure can occur unexpectedly and quickly, resulting in having to halt operations.

Proper Documentation

This next challenge is one that isn’t as commonly talked about, proper documentation.

Accurate and detailed documentation is vital for regulatory compliance, as inadequate records can lead to confusion, compliance breaches, and compromised research integrity.

Training and Compliance

Unfortunately, human error is a controlled environment challenge you may run into.

No matter how well designed, proper operation and procedure by staff determine performance of the cleanroom

Energy Efficiency

It’s time to think green.

Balancing the need for precise environmental conditions with energy efficiency is challenging if you don’t have innovative HVAC systems and energy management strategies to optimize resource consumption.

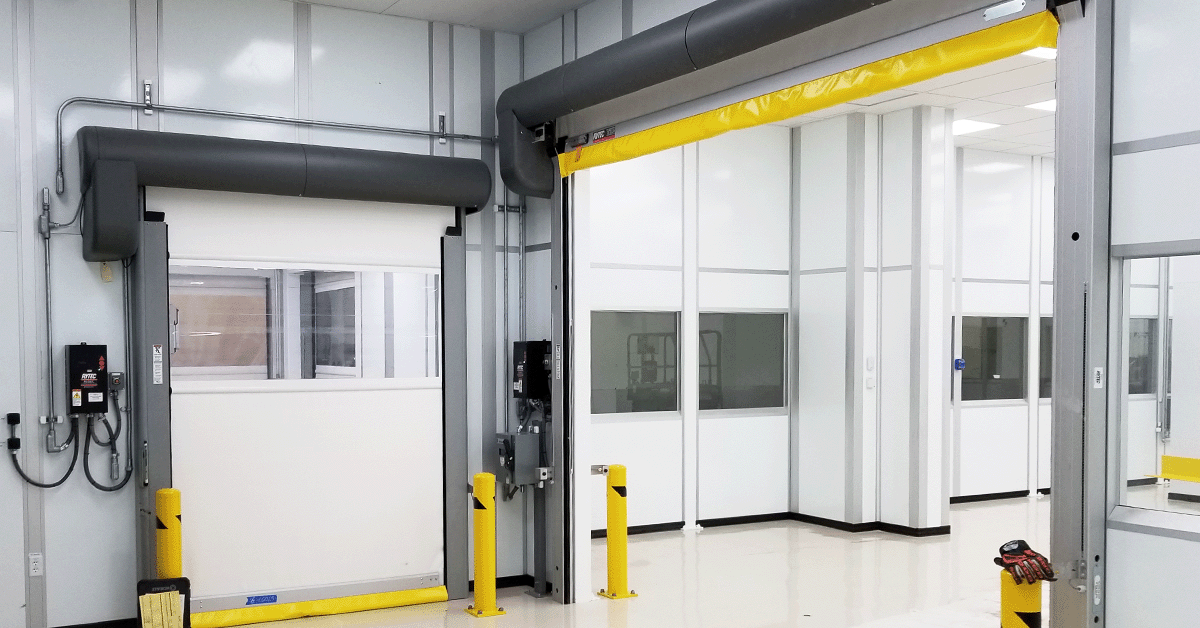

Space Constraints

When you build a controlled environment, you have to make sure your space is adequate. If you work with a solid cleanroom construction partner, they’ll take care of this.

Limited space can lead to overcrowding and inadequate airflow, impacting the uniformity of controlled conditions.

Regulatory Compliance

If an industry requires a controlled environment, there’s an extremely high chance strict regulations exist, and it’s very likely this will created a controlled environment challenge.

If you and your operation team aren’t up-to-date on the standard requirements of your industry, it can be easy to slip up. Federal standards and commercial best practices are a moving target that require constant attention and updating.

Data Security and Management

In the digital age, data security is paramount, as it’s unbelievably necessary to protect sensitive information and prevent unauthorized access.

Material Compatibility

Certain materials used in controlled environments may emit particles or gasses that comprise the environment’s purity.

If you’ve chosen the right CE provider, they’ll have conducted thorough material testing and selection are essential to maintain controlled conditions.

Strategies to Mitigate Controlled Environment Challenges

Now that we’ve covered the most common controlled environment challenges we’ve seen our customers encounter, we’d like to educate you on how to mitigate these issues through a few best practices.

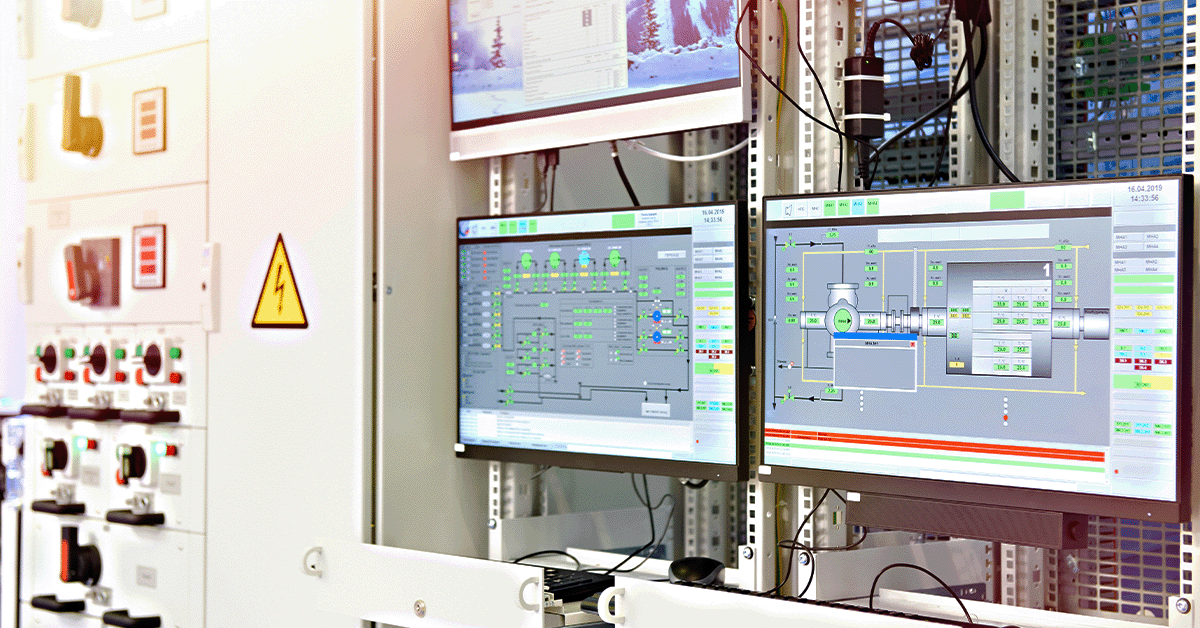

Advanced Monitoring Systems

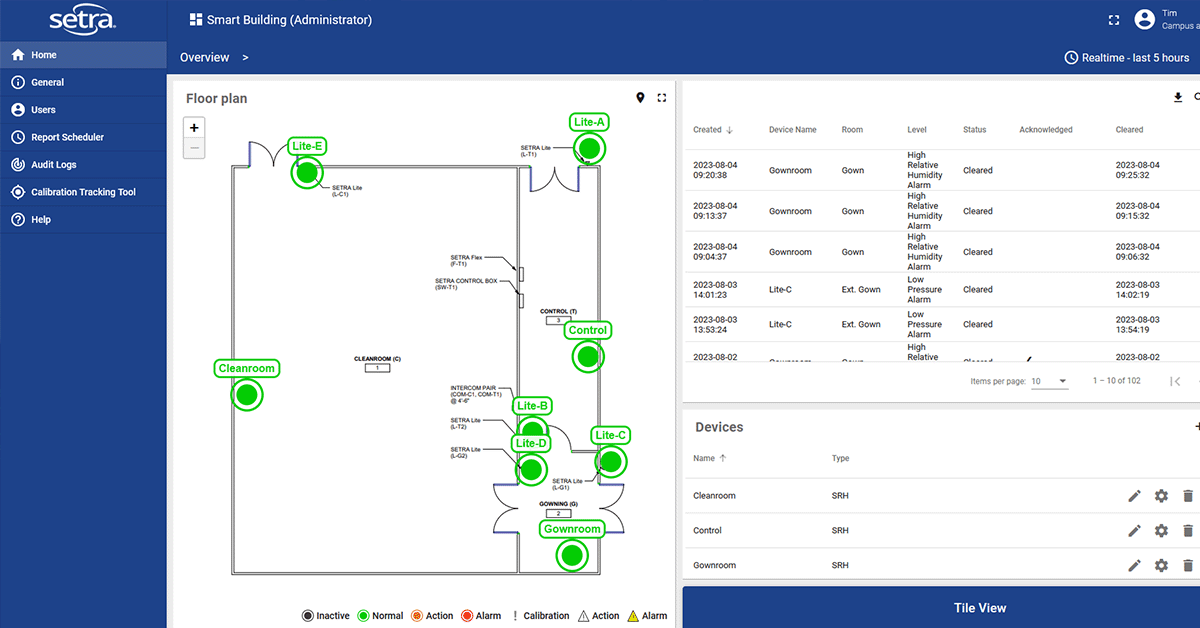

State-of-the-art monitoring systems provide real-time data on environmental conditions.

This enables timely interventions in response to deviations, preventing potential issues.

Regular Maintenance Protocols

Establishing routine maintenance schedules for equipment and systems minimizes the risk of unexpected failures and downtime.

If your operation can’t handle maintenance of your controlled environment, we can! Our team services all types of controlled environments across the United States.

You can easily get in touch with us here.

Quality Risk Management

Implementing quality risk management methodologies helps identify potential hazards and implement proactive measures to mitigate them.

Standard Operating Procedures (SOPs)

Well-defined SOPs ensure consistent processes and provide clear guidelines for personnel, reducing the likelihood of errors.

Training and Skill Enhancement

Continuous training enhances personnel competency and awareness, reducing the likelihood of deviations due to human error.

Innovative HVAC Systems

Modern HVAC systems offer precise control over temperature and humidity while optimizing energy consumption.

Given that your HVAC system is by far the most important component in your controlled environment, you need to make sure that you have the right one in place.

[elementor-template id=”3105″]

Optimized Space Utilization

Efficient space planning and layout ensure proper airflow and prevent overcrowding in controlled environments.

Like we mentioned, this will be handled by your controlled environment partner, as long as they’ve done their design work correctly.

Regular Monitoring

Dedicated personnel should monitor regulatory changes and ensure that the facility and processes remain compliant.

Cybersecurity Measures

Implementing robust cybersecurity protocols safeguards sensitive data from breaches and cyber threats.

Material Selection and Testing

Thoroughly assess and test materials for compatibility before introducing them into controlled environments.

Conclusion

Controlled environments are the backbone of industries that demand reliability, precision, and consistency.

Overcoming common controlled environment challenges requires a multi-faceted approach that encompasses technological innovation, robust protocols, comprehensive training, and adherence to regulations.

By recognizing and proactively addressing these challenges, professionals can ensure the integrity of their processes, products, and research outcomes.