*This post is part of a much larger pillar blog: The Complete Guide to Controlled Environments

Table of Contents

ToggleIntroduction

In a variety of sectors, modular cleanrooms are rising in popularity. This kind of cleanroom may be used for a variety of tasks, from manufacturing to medical and pharmaceutical operations, and is quick to build and simple to maintain.

In this blog post, we’ll be discussing what a modular cleanroom system is, and why a modular cleanroom design may be the best solution for you.

What is a Modular Cleanroom?

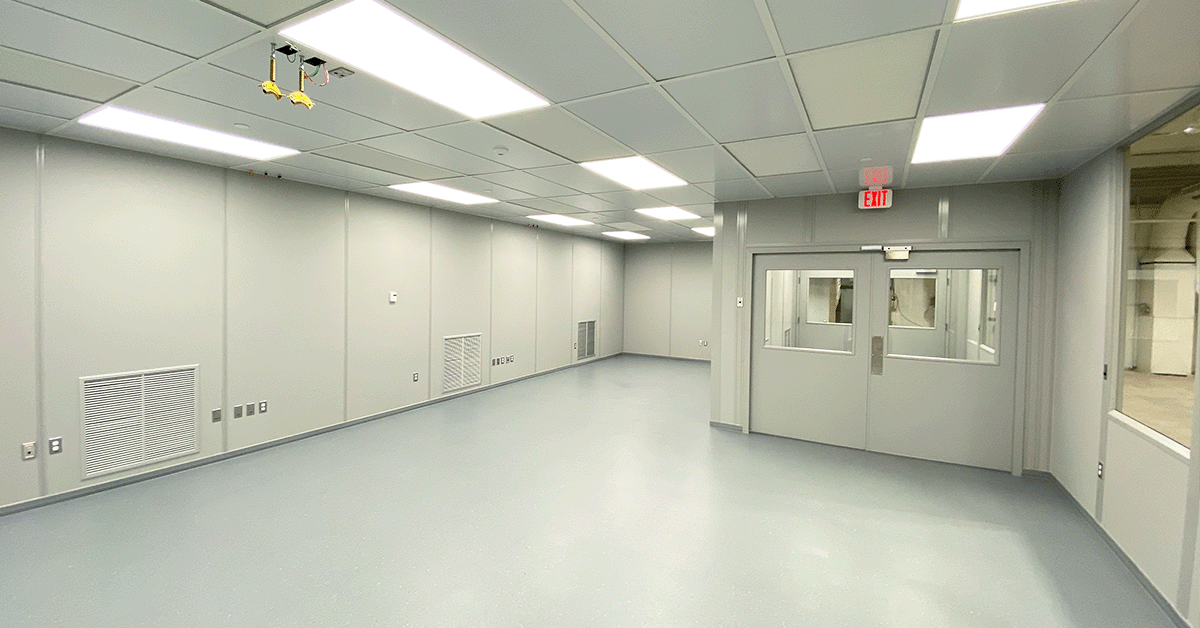

A modular cleanroom is a cleanroom that is constructed from prefabricated parts that are installed on-site according to your specifications.

These pre-fabricated parts include wall and ceiling panels as well as unique elements like air locks and pass-through chamber panels.

Depending on the use and classification requirements for your cleanroom, there are a variety of modular cleanroom design alternatives.

It is possible for modular cleanrooms to integrate existing walls and structures from your factory or facility or to stand alone as standalone buildings.

They can also use HVAC and already-existing equipment.

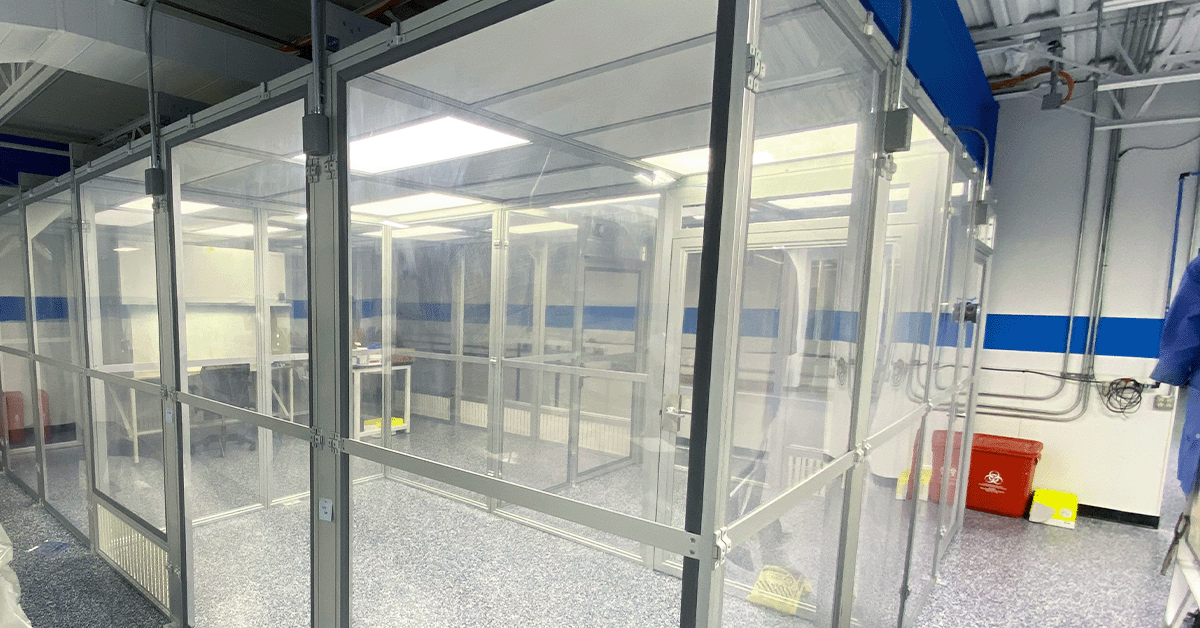

For increased flexibility and portability, modular cleanrooms might feature flexible walls that mimic tents or hard walls that resemble traditional construction.

Now that we’ve discussed what a modular cleanroom is, let’s talk about the benefits of building a modular cleanroom system.

Benefit #1 – Flexibility

The biggest benefit of a modular cleanroom system is flexibility.

In your facility, modular cleanrooms cause the least amount of interruption.

Additionally, modular cleanrooms are simple to change or extend; they may even be disassembled and rebuilt in a different site.

Moreover, despite the fact that the basic elements of modular cleanrooms are universal, you may still modify a modular cleanroom with a range of unique features and apparatus to ensure that the final product works well for your production.

The flexibility of a modular cleanroom is especially helpful for those who lease facilities, as you can take your cleanroom with you when you move.

Benefit #2 – Ease of Installation

Like we mentioned previously, modular cleanrooms cause the least amount of interruption due to the speed and ease of their installation.

The modular cleanroom panel systems are fabricated off-site and come to the facility, meaning our team is able to erect and place the cleanroom with very little on-site field fabrication.

In traditional cleanroom production, many trade processes need to be involved, slowing construction time and increasing the budget required for construction.

Also, modular cleanrooms are much cleaner due to the lack of sanding, taping, and other processes required in traditional construction.

Benefit #3 – Multiple Panel Finish Options

No two cleanrooms are used for the same process. As a result, different finishes on wall panels are required.

Regardless of the industry you’re in, modular wall panels can be finished in a way that suits your process.

We even sometimes see that two cleanrooms for the same process may require different finishes.

For example, one customer needed a vinyl covered GYP room and a room with FRP steel studs due to the placement of each cleanroom in the facility.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of your industry with our weekly e-newsletter.

Benefit #4 – Tax Benefits

Modular cleanrooms are treated as a piece of equipment, meaning they depreciate yearly as equipment instead of traditional construction that is classified as real estate.

Conclusion

In conclusion, building a modular cleanroom has many fantastic benefits compared to traditional construction. It may not be for everyone, but use this blog post as a way to help determine if it’s right for you.

As always, if you have any questions about cleanroom design, our team is here to help.

If you need help building a modular cleanroom, contact us.