*This post is part of a much larger pillar blog: The Complete Guide to Controlled Environments

Table of Contents

ToggleIntroduction

When you hear the term “cleanroom,” you might picture a space-age lab filled with scientists in white suits.

While that’s not too far off, cleanrooms are critical environments used in various industries, from pharmaceuticals to electronics.

But what makes a cleanroom truly “clean”? A big part of the answer lies in the air change rates.

In this article, we’ll be going in-depth on all things air change rates. If you have any questions after reading this, make sure to check out the FAQ at the bottom, or feel free to contact us.

FYI – ACR is often called ACH. (Air Changes per Hour).

Understanding Air Change Rates

To kick things off, let’s make sure you have a total understanding of what air change rates are, and why they’re so important.

Definition of Air Change Rate (ACR or ACH)

Air Change Rate (ACR) is a key metric in cleanroom design. It refers to the number of times the air within a room is replaced with fresh air in an hour. Imagine your living room having all its air replaced 20 times an hour; that’s an example of a high ACR.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of your industry with our weekly e-newsletter.

How ACR is Measured

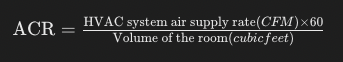

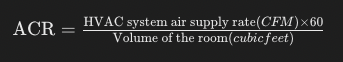

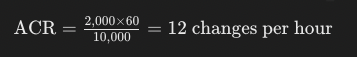

Like we just mentioned, ACR is measured in changes per hour (CPH). This rate is calculated using the formula:

We’ll go more into detail on this formula later, but it’s important we introduce it early on.

The Role of Air Change Rates in Cleanroom Design

The air change rate inside of a controlled environment can have a lot of impact on how we design the room itself. This is because of factors like contaminate control, temperature and humidity regulation, and pressure control amongst others.

Contaminant Control

The primary function of ACR in a cleanroom is to control contamination. Higher ACR means more frequent air replacement, reducing the number of particles and microbes in the air.

Temperature and Humidity Regulation

Proper ACR also helps maintain the desired temperature and humidity levels, essential for certain sensitive processes and materials.

Pressure Control

Maintaining positive or negative pressure is crucial in preventing contaminated air from entering or exiting the cleanroom. ACR plays a significant role in sustaining these pressure levels.

Standards and Guidelines for Air Change Rates

Let’s take a look at some of the standards and guidelines that exist surrounding air change rates.

ISO Standards for Cleanrooms

The International Organization for Standardization (ISO) provides specific standards for cleanrooms, such as ISO 14644. These standards classify cleanrooms based on the number and size of particles allowed per cubic meter of air, indirectly influencing ACR requirements.

More strict ISO classification means you’ll need to have a higher ACR to accomplish the level of cleanliness you’re aiming for.

For example, in an ISO 7 cleanroom you have to aim for 60 ACH (Air Changes per Hour)

FDA Guidelines

In the pharmaceutical industry, the FDA has stringent guidelines for cleanroom operations, emphasizing the need for proper ACR to ensure product safety and efficacy. With a higher ACR, you can have a more sterile and effective product.

Other Industry-Specific Guidelines

Various industries, such as electronics and biotechnology, have their own guidelines that specify ACR to ensure their cleanrooms meet necessary cleanliness levels. If you’re building a cleanroom for this purpose, navigating this can be a bit tricky. Make sure to get in touch with a cleanroom expert to design the solution with the right ACR.

Factors that Influence Air Change Rates

Now that we know what ACR is, its role, and some standards associated with it, let’s look at some of the biggest factors that affect it.

Cleanroom Classification

Different cleanroom classifications (e.g., ISO Class 5 vs. ISO Class 8) require different ACRs. Higher classifications (lower class numbers) typically need higher ACRs. Like we mentioned previously, you’ll need to design your room with ACR capabilities required for your classification.

Types of Processes and Activities

Processes that generate more particles, like certain manufacturing operations, require higher ACRs to maintain air cleanliness. We see this a lot in the automotive industry.

Occupancy Levels

The number of people in a cleanroom can impact ACR needs. More occupants generally mean higher ACR requirements to counteract the additional contamination they bring. More people equals more potential contaminants.

Calculating Air Change Rates

We touched on it very briefly before, but let’s go more into detail on ACR calculations, and run through a sample.

Formula for ACR Calculation

We showed you it before, but here it is again. The formula to calculate ACR is straightforward but crucial:

Example ACR Calculation

For example, if a cleanroom has a volume of 10,000 cubic feet and an HVAC system supplying 2,000 cubic feet per minute (CFM), the ACR would be:

The Impact of Insufficient Air Change Rates

What happens if you don’t have a sufficient ACR in your cleanroom?

Risk of Contamination

If ACR is too low, contaminants can accumulate, leading to product defects and compromised research results.

Impact on Product Quality

Products manufactured in environments with insufficient ACR are at higher risk of contamination, affecting their quality and safety.

Health Risks to Personnel

Low ACR can lead to a buildup of harmful particles and chemicals, posing health risks to employees working in the cleanroom.

Benefits of Optimal Air Change Rates

Okay, so now that we’ve got the negative effects of a low ACR out of the way, let’s look at some of the benefits of having an appropriate level of ACR.

Enhanced Contamination Control

Proper ACR ensures that contaminants are swiftly removed, maintaining the cleanroom’s integrity.

Improved Product Quality

Maintaining optimal ACR directly impacts product quality, ensuring that they meet stringent safety and efficacy standards.

Better Working Conditions

A clean environment is not only crucial for products but also for the health and comfort of personnel working within the cleanroom.

Technologies and Systems for Managing Air Change Rates

Every industry is being propelled quickly by technology, and the cleanroom market is no different. Due to recent advancements, it’s easier than ever before to create and maintain you’re desired ACR.

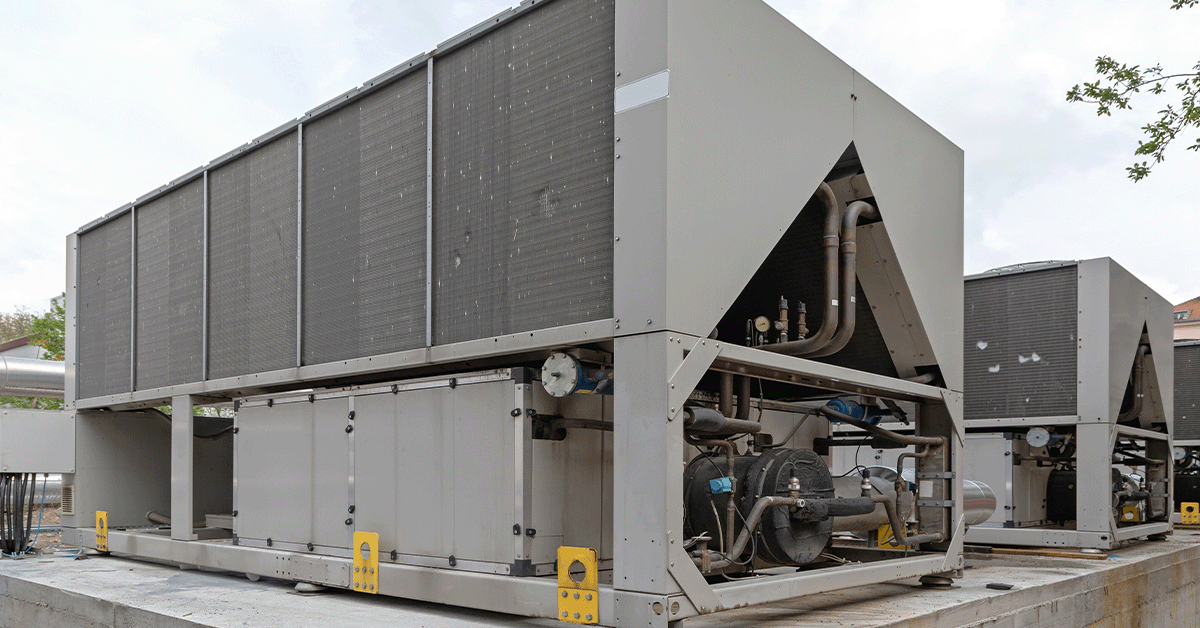

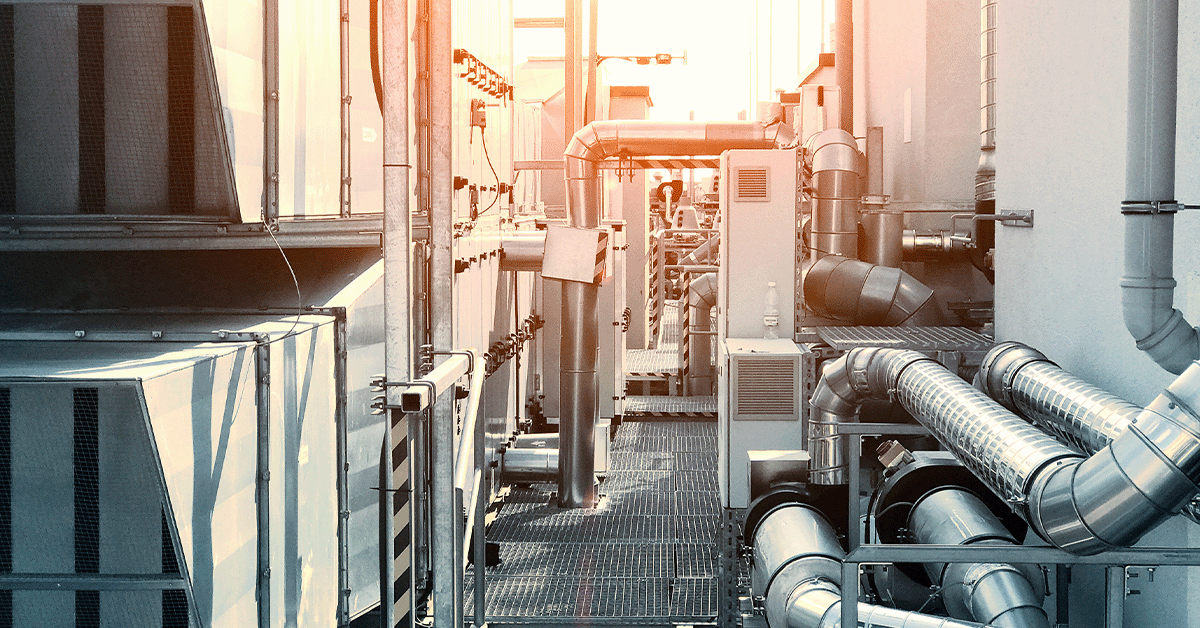

HVAC Systems

HVAC (Heating, Ventilation, and Air Conditioning) systems are the backbone of cleanroom air management, designed to provide controlled air changes. As time goes on, more efficient HVAC systems have been developed, helping make this so much easier.

HEPA Filters

High-Efficiency Particulate Air (HEPA) filters trap particles, ensuring that the air supplied to the cleanroom is free of contaminants. This makes it so your system doesn’t have to work as hard.

Laminar Flow Hoods

Laminar flow hoods provide a continuous flow of filtered air to specific areas within the cleanroom, ensuring localized high air quality. This propels your ACR without putting as much stress on the unit.

Energy Efficiency and Air Change Rates

Now more than ever, it’s increasingly important to be energy efficient constantly in your room.

Balancing Energy Use and Air Quality

While high ACR is essential for cleanliness, it can also increase energy consumption. Balancing these needs is crucial for sustainable operation.

Energy-Saving Technologies

Advanced HVAC systems and energy recovery ventilators can help reduce the energy footprint of maintaining high ACRs.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of your industry with our weekly e-newsletter.

Challenges in Maintaining Proper Air Change Rates

What are some of the most common challenges when aiming to achieve a specific ACR?

Maintenance Issues

Regular maintenance of HVAC systems and filters is essential to ensure they function correctly and maintain the desired ACR.

Monitoring and Control

Constant monitoring of ACR is necessary to adapt to changes in cleanroom use and to detect any deviations from desired levels.

Cost Considerations

Implementing and maintaining systems to achieve optimal ACR can be costly, requiring a balance between investment and benefits.

Conclusion

In cleanroom design, air change rates are a cornerstone of maintaining the stringent conditions necessary for high-quality production and research. From controlling contamination to ensuring the health of personnel, proper ACR is essential. By understanding and implementing optimal air change rates, industries can safeguard their processes, products, and people.

If you need help achieving a specific ACR for your cleanroom, contact us.

FAQs

What is the ideal air change rate for a cleanroom?

The ideal air change rate varies depending on the cleanroom classification and industry standards. For example, an ISO Class 5 cleanroom typically requires an ACR of 240-480 changes per hour.

How often should air change rates be monitoring?

Air change rates should be continuously monitored to ensure they meet the required standards. Regular maintenance and periodic checks are also essential to maintain optimal conditions.

Can air change rates affect employees health?

Yes, proper air change rates help remove harmful particles and contaminants, ensuring a safer working environment for employees.

What technologies help maintain air change rates?

Technologies such as HVAC systems, HEPA filters, laminar flow hoods, and advanced monitoring systems are critical in maintaining appropriate air change rates.

Are there differences in air change rates for different industries?

Yes, different industries have specific requirements based on the sensitivity of their processes and the level of contamination control needed. For example, pharmaceutical cleanrooms have different ACR needs compared to semiconductor manufacturing cleanrooms.