Table of Contents

ToggleIntroduction

Framing is the backbone of any building, providing the structure and support necessary for stability and integrity.

It involves creating a skeleton of the building using materials that ensure the overall strength and durability of the construction. Choosing the right framing material is crucial as it impacts the building’s performance, cost, and longevity.

This article aims to provide a comprehensive comparison of metal framing versus wood framing, focusing on cost and performance. By evaluating these two popular framing materials, we seek to help builders, architects, and property owners make informed decisions for their construction projects.

To start things off, let’s talk in-depth about key information for both materials.

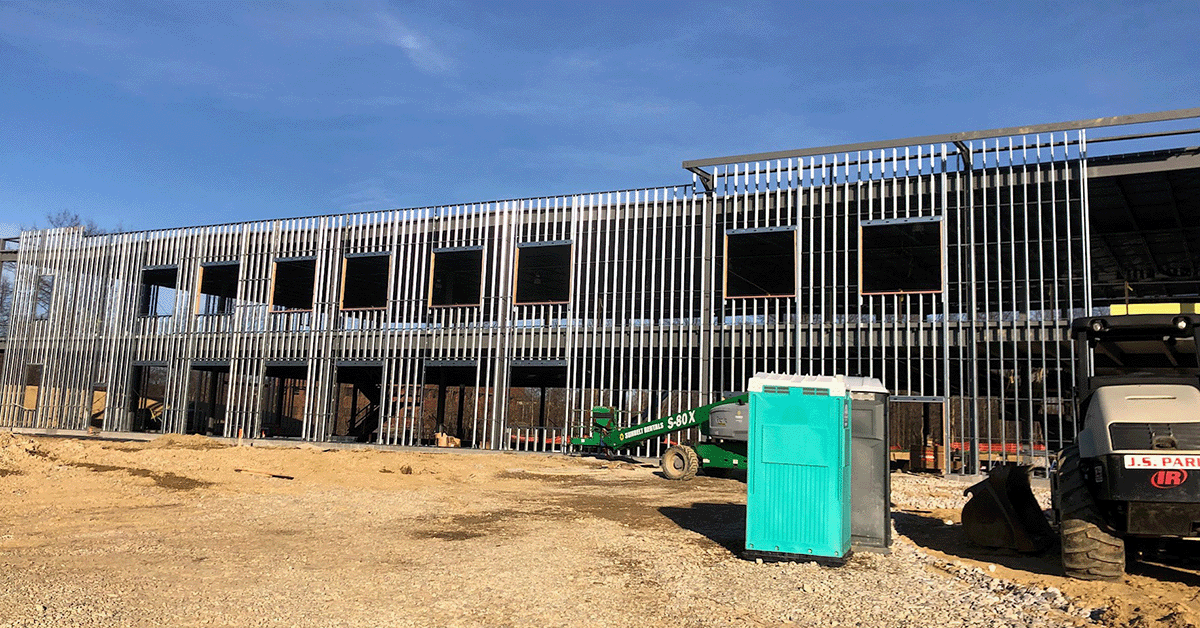

Understanding Metal Framing

In these next few sections, we’ll be discussing the different types of metal framing, the characteristics that make metal framing unique, and some different applications you could use it for. This is the type of framing that AVM specializes in, so we know what we’re talking about.

Types of Metal Framing

- Light-Gauge Steel Framing: Commonly used in residential and light commercial construction, light-gauge steel is known for its flexibility and ease of use.

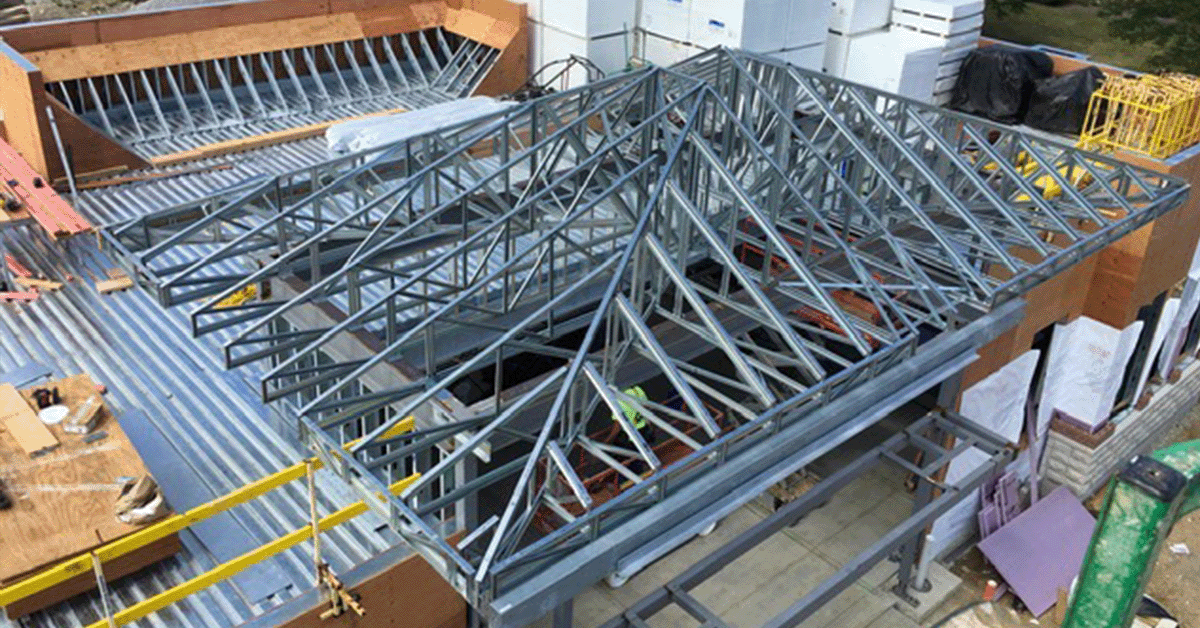

- Structural Steel Framing: Utilized in larger commercial and industrial projects, structural steel provides robust support for high-load applications.

Characteristics of Metal Framing

- Strength and Durability: Metal framing, particularly steel, offers superior strength and can withstand significant stress without bending or breaking.

- Resistance to Pests and Decay: Metal is impervious to termites, rodents, and other pests, unlike wood which can be severely damaged by these invaders.

- Fire Resistance: Steel framing does not combust, adding a layer of safety in fire-prone areas.

- Sustainability and Recyclability: Metal, especially steel, is highly recyclable, making it an environmentally friendly option.

Applications of Metal Framing

Metal framing is necessary for commercial buildings, industrial structures, and multi-story residential buildings due to its strength and durability. It is also favored for structures requiring non-combustible materials, such as hospitals and schools.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of the construction industry with our weekly e-newsletter.

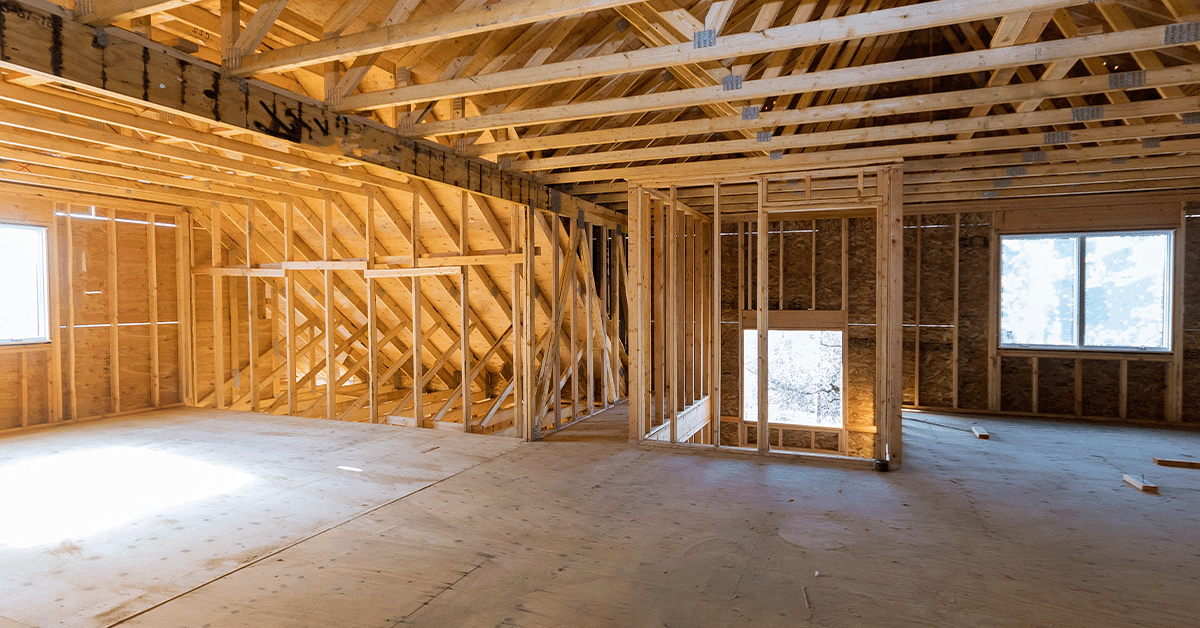

Understanding Wood Framing

Now that we’ve thoroughly explained metal framing, it’s time to discuss the less common option, wood framing. Just like the section above, we’ll be covering different types, characteristics, and common applications.

Types of Wood Framing

- Softwood vs. Hardwood: Softwood (e.g., pine) is commonly used for framing due to its availability and cost-effectiveness, while hardwood (e.g., oak) is used in specific applications requiring additional strength.

- Dimensional Lumber: Standard sizes of wood used in framing construction.

- Engineered Wood Products: Includes laminated veneer lumber (LVL), glulam, and cross-laminated timber (CLT), which offer enhanced strength and stability.

Characteristics of Wood Framing

- Natural Thermal Insulation: Wood provides good thermal insulation, reducing energy costs for heating and cooling.

- Ease of Handling and Installation: Wood is relatively easy to cut, shape, and assemble, making it a popular choice for quick construction.

- Aesthetic Appeal and Versatility: Wood offers a warm, natural look and can be easily modified or expanded.

- Environmental Impact and Sustainability: Wood is a renewable resource, and sustainably managed forests can provide an ongoing supply of building material.

Applications of Wood Framing

Wood framing is predominantly used in residential homes, low-rise commercial buildings, and extremely small-scale industrial structures due to its cost-effectiveness and ease of use.

Cost Comparison

Aside from just the cost of the materials, you should also be aware of labor costs, and what employing these types of framing will mean long-term.

Initial Material Costs

- Metal Framing: Generally more expensive per unit compared to wood, influenced by market prices for steel and manufacturing costs.

- Wood Framing: Typically less expensive initially, though prices can fluctuate based on supply and demand, particularly for certain types of wood.

Labor Costs

- Metal Framing: Requires specialized skills and tools, which can increase labor costs. However, the precision and speed of installation with metal framing can offset some of these expenses.

- Wood Framing: Easier to work with, often resulting in lower labor costs. Carpenters and general contractors are more familiar with wood, making it a more straightforward process.

Long-term Costs

- Maintenance and Repairs:

- Metal Framing: Lower maintenance needs due to its resistance to pests and decay. However, it may require occasional treatments to prevent rust in certain environments.

- Wood Framing: Higher maintenance due to susceptibility to termites, rot, and warping. Regular inspections and treatments are necessary.

- Lifespan and Durability:

- Metal Framing: Generally has a longer lifespan and better durability under extreme conditions.

- Wood Framing: Adequately maintained wood structures can also last long, but they are more vulnerable to environmental factors.

- Insurance Premiums:

- Metal Framing: Often lower due to non-combustibility and resistance to pests.

- Wood Framing: Potentially higher due to fire risk and pest issues.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of the construction industry with our weekly e-newsletter.

Performance Comparison

There are a few really important things to look at when you’re considering performance. This includes structural strength, environmental resistance, insulation, sustainability, and adaptability and versatility.

Structural Strength and Load-Bearing Capacity

- Metal Framing: Offers superior tensile strength and can handle larger loads without compromising structural integrity.

- Wood Framing: Provides excellent compressive strength and flexibility, making it ideal for various design applications.

Environmental and Weather Resistance

- Metal Framing: Highly resistant to moisture, pests, and fire, making it suitable for diverse climates.

- Wood Framing: Prone to moisture damage, pests, and fire, but treatments and protective measures can mitigate these issues.

Thermal and Acoustic Insulation

- Metal Framing: Can suffer from thermal bridging, leading to heat loss unless properly insulated. Metal also transmits sound more easily.

- Wood Framing: Naturally better at insulating against heat and sound, providing a more comfortable and quieter environment.

Sustainability and Environmental Impact

- Metal Framing: Recyclable and can be sourced from recycled materials, but production is energy-intensive.

- Wood Framing: Renewable and can sequester carbon, but overharvesting and deforestation are concerns. Sustainable forestry practices are essential.

Adaptability and Versatility

- Metal Framing: Offers great design flexibility and can be prefabricated for efficiency. Modifications can be challenging post-installation.

- Wood Framing: Easy to modify and adapt, making it suitable for customized and intricate architectural details.

Practical Considerations for Choosing Framing Material

Here’s a few other factors we think are important to consider.

Project Type and Scale

- Metal Framing: Ideal for large commercial projects, multi-story buildings, and structures requiring high strength.

- Wood Framing: Best suited for residential homes, low-rise buildings, and smaller-scale projects.

Climate and Environmental Factors

- Metal Framing: Preferred in humid, pest-prone, or fire-prone areas.

- Wood Framing: Suitable for regions with moderate climates and where pest control measures are manageable.

Budget Constraints and Long-term Goals

- Metal Framing: Higher upfront investment with potentially lower long-term costs due to durability and low maintenance.

- Wood Framing: Lower initial cost but possibly higher long-term expenses for maintenance and repairs.

Regulatory and Code Requirements

- Metal Framing: Compliance with stringent fire safety and structural codes can be easier.

- Wood Framing: Must meet building codes for fire safety, insulation, and structural integrity, which can vary significantly by region.

Pros and Cons Summary

Now that all the most important factors are laid out in extreme detail, it’s time to compare!

Metal Framing

- Pros:

- High strength and durability

- Excellent resistance to fire, pests, and decay

- Sustainable and recyclable

- Cons:

- Higher initial costs

- Requires specialized labor and tools

- Potential issues with thermal bridging

Wood Framing

- Pros:

- Cost-effective with lower initial costs

- Natural insulation properties

- Easy to handle, modify, and install

- Aesthetic and versatile

- Cons:

- Susceptible to pests, moisture, and fire

- Higher maintenance requirements

- Environmental impact if not sourced sustainably

Conclusion

This comparison of metal vs. wood framing has highlighted the essential aspects of both materials, focusing on cost, performance, and practical considerations. Metal framing offers superior strength, durability, and resistance to pests and fire but comes with higher initial costs and specialized labor needs. Wood framing, on the other hand, is cost-effective, easy to work with, and provides natural insulation, but requires diligent maintenance and pest control.

Choosing between metal and wood framing depends on various factors, including the project’s scale, budget, environmental conditions, and long-term goals. Both materials have their advantages and limitations, and the decision should be based on a comprehensive assessment of these factors.

We encourage readers to assess their specific project needs and consult with construction professionals to determine the best framing material. Considering both immediate and future implications of the choice will lead to more sustainable, cost-effective, and high-performance building outcomes. By prioritizing the right balance between cost and performance, builders can ensure the success and longevity of their projects.

Need help with metal stud framing? Contact us.