Table of Contents

ToggleIntroduction

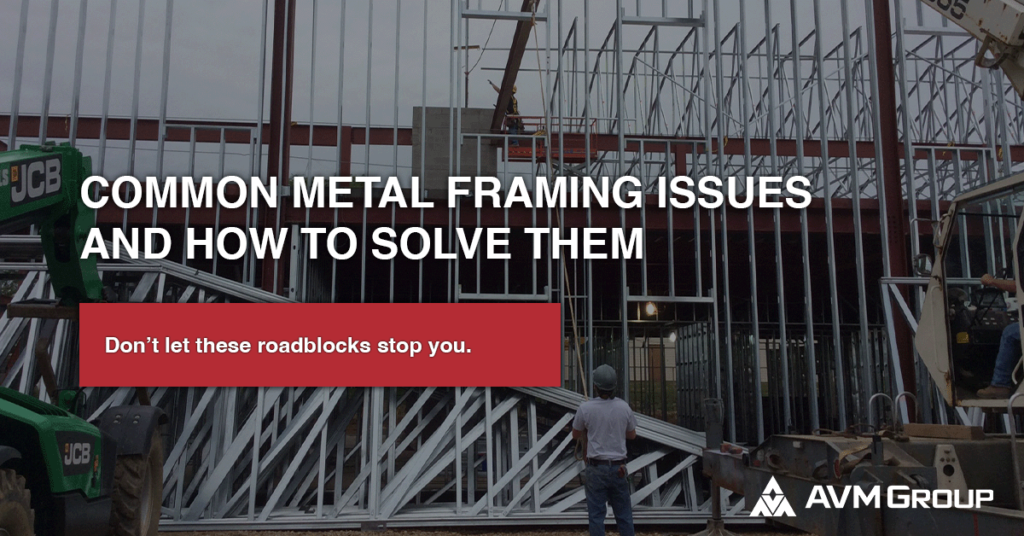

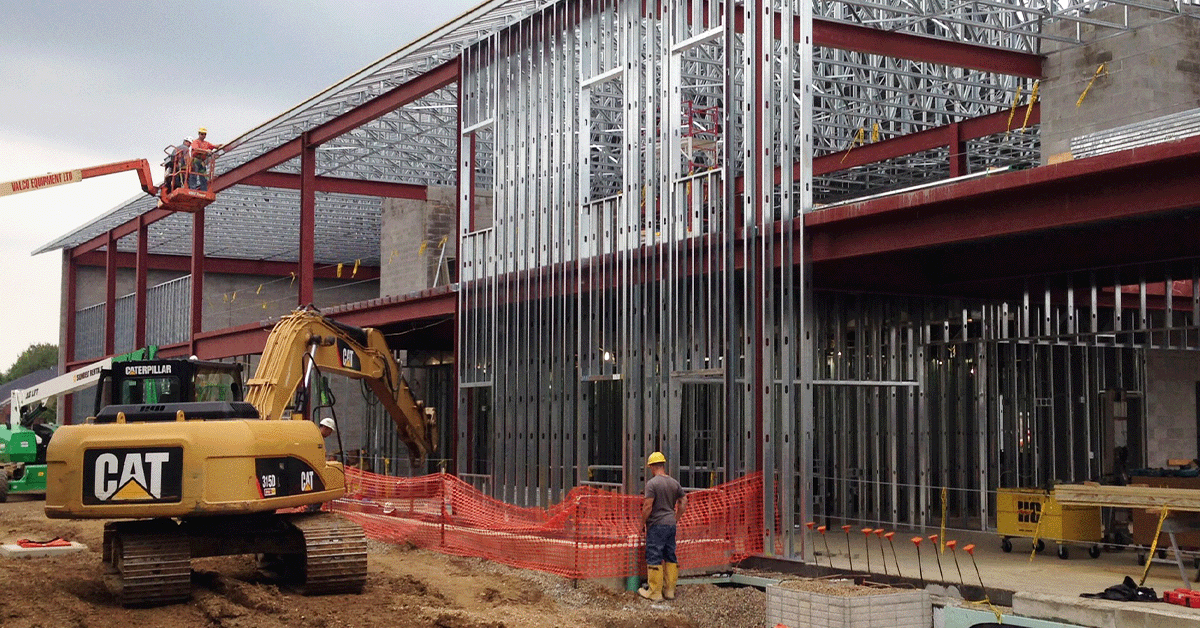

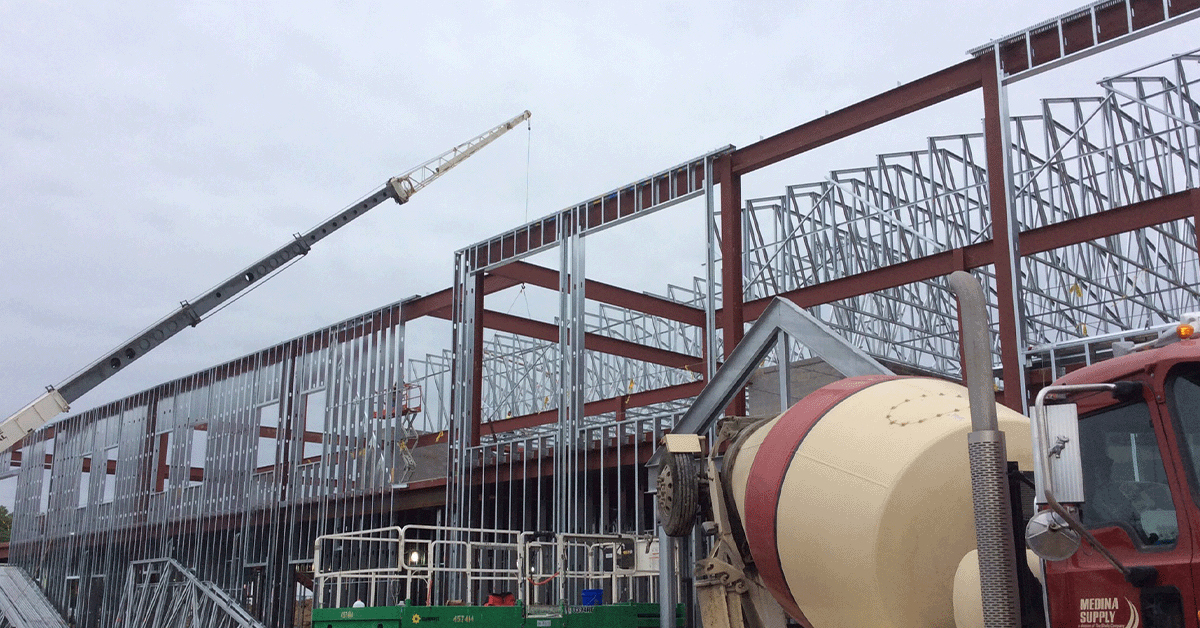

Metal framing is becoming increasingly popular in construction due to its durability, strength, and versatility. However, like any building material, metal comes with its own set of challenges.

Proper installation is crucial to ensure the longevity and functionality of metal-framed structures.

In this article, we’ll explore the common challenges faced during metal framing installation and provide practical solutions to overcome them.

We’ve even provided a comprehensive FAQ section at the bottom of this article to answer any extra questions you may have.

Let’s get started!

Understanding Metal Framing

Before we get into the nitty gritty of the most common challenges that occur with metal framing, let’s quickly go over what metal framing is, just in case you need a refresher.

What is Metal Framing?

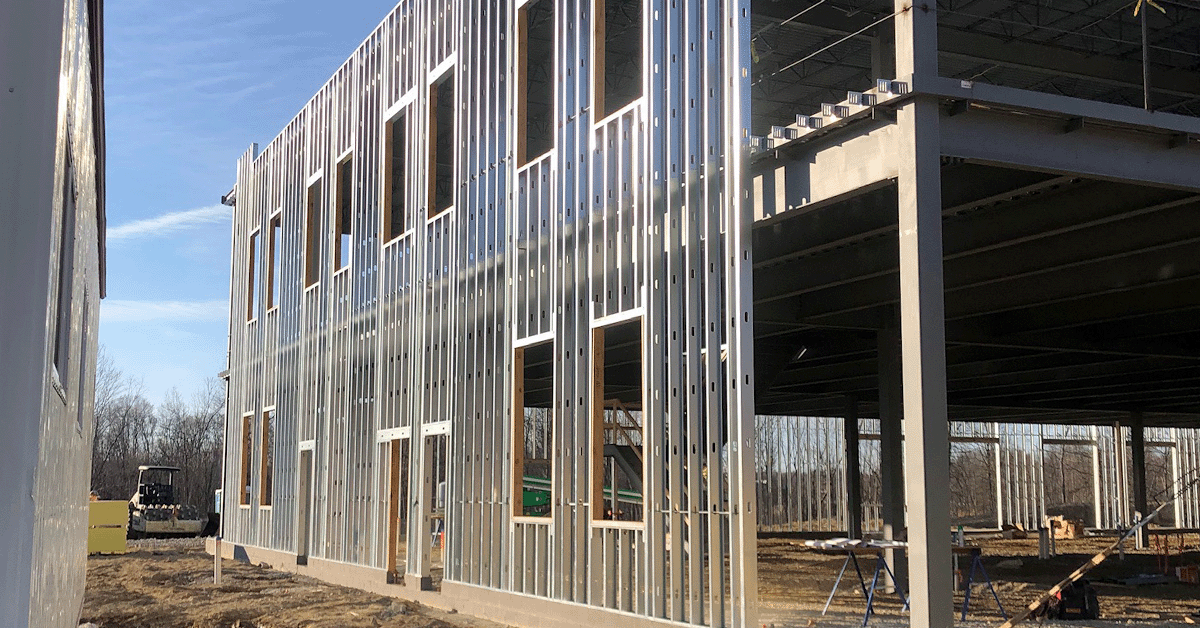

Metal framing involves the use of steel or aluminum to construct the skeleton of a building.

This method is favored for its strength, fire resistance, and the ability to create more precise and straight structures compared to traditional wood framing.

Check out this article we wrote comparing metal framing to wood.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of the construction industry with our weekly e-newsletter.

Types of Metal Framing

There are primarily two types of metal framing:

- Light Gauge Steel Framing: Commonly used in residential and light commercial construction.

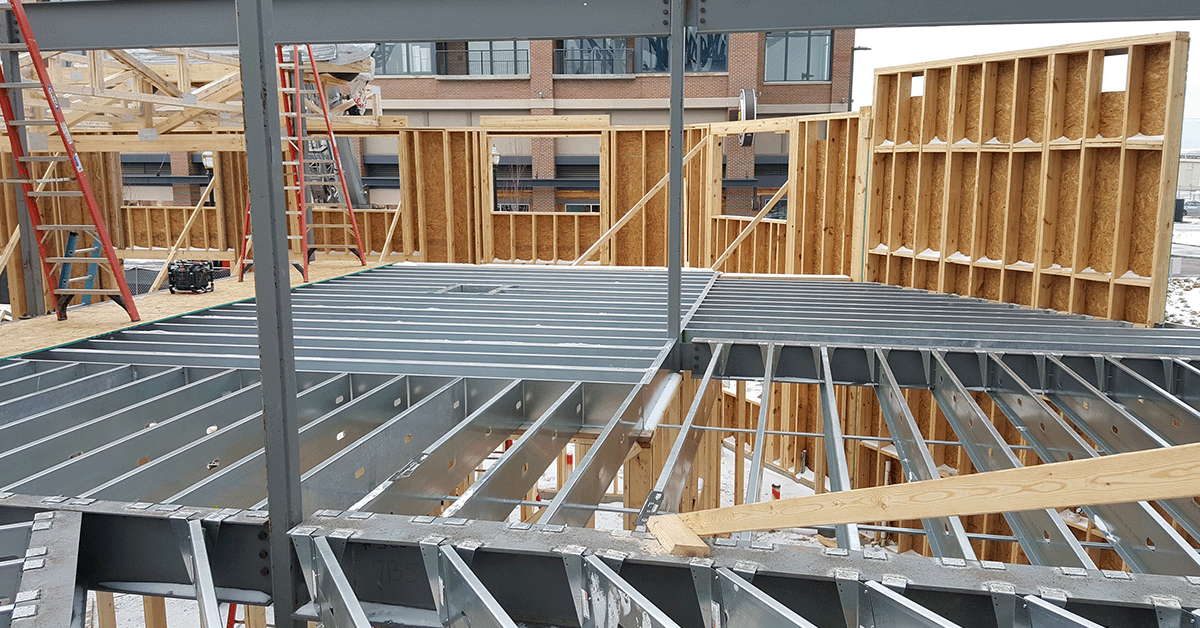

- Structural Steel Framing: Used in larger, more complex projects such as skyscrapers and industrial buildings.

Common Challenges in Metal Framing Installation

Alright, it’s time to look at the most common challenges experienced with metal framing. However, don’t fret! We’ll be going into a variety of solutions to these issues later in the article.

It’s also very important to note that if you work with an experienced metal frame installation company, you more than likely won’t experience these issues.

Misalignment Issues

One of the primary challenges is ensuring that all components are perfectly aligned. Misalignment can lead to structural weaknesses and aesthetic issues.

Difficulty in Cutting and Fitting

Cutting metal to the correct size and fitting it precisely can be a tough job, requiring specialized tools and skills.

Dealing with Corrosion

Metal is susceptible to rust and corrosion, especially in humid or coastal environments.

Managing Thermal Expansion and Contraction

Metal expands and contracts with temperature changes, which can cause structural instability if not properly managed.

Soundproofing Concerns

Metal framing can sometimes act as a conduit for sound, leading to noise issues in the building.

Handling Heavy Loads

Ensuring that the metal frame can support heavy loads without bending or breaking is essential for the safety and integrity of the structure.

Fire Resistance Requirements

While metal itself is non-combustible, ensuring that the overall structure meets fire safety standards is a significant concern.

Electrical and Plumbing Integration

Integrating electrical and plumbing systems into metal framing can be more complex compared to wood framing.

Cost Management

Metal framing can be more expensive than traditional materials, so managing costs effectively is crucial.

Ensuring Structural Integrity

Maintaining the structural integrity of the frame throughout the construction process is vital to prevent future issues.

Working in Adverse Weather Conditions

Adverse weather can slow down or complicate the installation process, especially if the metal becomes slippery or too hot to handle.

Coordination with Other Trades

Coordinating with electricians, plumbers, and other trades is often more complex in metal-framed buildings.

Safety Concerns

Handling metal framing materials can pose safety risks, including cuts, falls, and other injuries.

Solutions to Overcome Metal Framing Challenges

Okay, enough doom and gloom! Let’s solve these challenges.

Ensuring Accurate Measurements

Using precise measuring tools and double-checking measurements can prevent misalignment issues. Laser levels and other advanced tools can help achieve perfect alignment.

Using the Right Tools and Techniques

Investing in high-quality tools and training workers in the best techniques for cutting and fitting metal can save time and reduce errors.

Applying Anti-Corrosion Treatments

Using galvanized steel or applying anti-corrosion coatings can significantly reduce the risk of rust and corrosion.

Thermal Insulation Solutions

Incorporating thermal breaks and using insulating materials can help manage the expansion and contraction of metal framing.

Soundproofing Strategies

Adding insulation and using sound-dampening materials can mitigate noise issues associated with metal framing.

Load Distribution Techniques

Ensuring that the load is evenly distributed across the frame and using reinforcements where necessary can prevent structural failures.

Fireproofing Methods

Using fire-resistant coatings and ensuring that all materials meet fire safety standards can enhance the fire resistance of metal-framed structures.

Integration Techniques for Electrical and Plumbing Systems

Pre-planning the integration of electrical and plumbing systems can simplify the process. Using pre-punched holes in metal studs can make the installation easier.

Cost-Saving Tips

Buying materials in bulk, optimizing design to reduce waste, and efficient project management can help keep costs down.

Quality Assurance Practices

Regular inspections and quality checks can ensure that the metal framing is installed correctly and will stand the test of time.

Weather Adaptation Strategies

Planning the installation process around weather forecasts and using weather-resistant materials can mitigate the impact of adverse weather.

Effective Coordination with Other Trades

Regular meetings and clear communication with other trades can ensure that everyone is on the same page and working efficiently.

Adhering to Safety Protocols

Providing proper training, using personal protective equipment (PPE), and adhering to safety protocols can minimize the risk of accidents and injuries.

Conclusion

In conclusion, installing metal framing can be challenging, but with the right knowledge and metal stud framing construction company, these challenges can be effectively managed.

From ensuring accurate measurements to integrating electrical systems, each step requires careful planning and execution.

By following the solutions outlined above, you can overcome the common challenges and ensure a successful metal framing installation.

If you need metal framing for your commercial build, contact us.

FAQs

What is the most common problem in metal framing installation?

The most common problem is misalignment, which can lead to structural weaknesses and aesthetic issues.

How can I prevent corrosion in metal framing?

Using galvanized steel or applying anti-corrosion treatments can help prevent rust and corrosion.

What are the best practices for soundproofing in metal framing?

Adding insulation and using sound-dampening materials can effectively address soundproofing concerns.

How do I ensure the structural integrity of metal framing?

Ensuring accurate measurements, regular quality checks, and using load distribution techniques can help maintain structural integrity.

What safety measures should be taken during metal framing installation?

Proper training, using PPE, and adhering to safety protocols are essential to minimize risks during installation.