In the world of high-precision manufacturing, pharmaceuticals, and biotechnology, having the right environment is crucial to production. However, choosing whether to build a new cleanroom environment with AVM’s modular options or to retrofit an existing space in your facility can be difficult. The decision between new construction and retrofitting isn’t just a matter of real estate—it is a strategic choice that can impact your compliance, operational flow, and bottom line for years to come.

Table of Contents

ToggleNew Construction Vs. Retrofit: Definitions And Use Cases

Before getting into the details of which is better for your space, it’s important to understand the difference between these two options.

New Construction Cleanrooms:

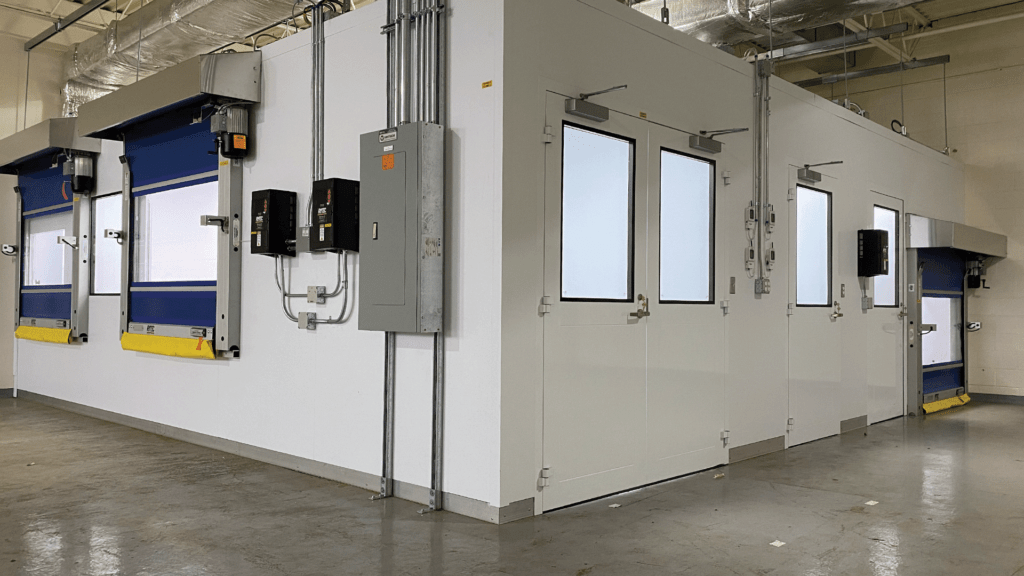

These modular systems are built and designed to provide the highest level of control for airborne contaminants. They can easily be moved or modified, and use rigid walls to restrict access through a designated entryway. They can be built using recirculating air systems or single-pass systems based on your needs.

Retrofitting Cleanroom Construction:

These cleanrooms are built using the space and systems you already have present in your facility. Retrofitted environments are built to the same standards as our modular cleanrooms, but this can require additional time and work to ensure all aspects are compliant.

Why Facility Strategy Matters In Controlled Environments

A cleanroom is not just a static space – it’s a dynamic piece of equipment that drastically impacts your company’s production and overall success. If the facility strategy is flawed, it can lead to bottlenecks in production or, worse, catastrophic contamination failures.

Before choosing whether you should retrofit or construct a new cleanroom, the key question to ask yourself is how will this build affect my current processes?

Important factors to consider about the construction process of new construction cleanrooms and retrofitted cleanrooms:

New Construction:

Typically takes place in an existing empty site, warehouse, or wing, which can help to minimize day-to-day disruption to current staff and operations, but can also present its own challenges, such as site selection considerations and added infrastructure costs.

Retrofitting:

Involves construction within an existing space or building that may not have been originally constructed with this use in mind. Retrofitting can require rigorous dust-containment protocols, noise management, and potential temporary shutdowns of adjacent clean zones, but can also sometimes be completed more quickly than new construction would.

How Each Can Affect Your Facility

While it’s true that construction in any form is likely to disrupt other environments or processes within your facility, it’s important to remember that each client and facility is different. During the discovery and planning phase of your cleanroom construction project, the AVM team will work closely with you to determine the best course of action. Many retrofitting construction projects require at least some demolition to fully construct and finish a cleanroom environment, so if demolition is too disruptive for your facility’s needs, then it’s more likely that a new construction is a better choice. Consider whether your facility can handle a pause in production during demolition, if sound control will be necessary, and if construction or demolition in a particular location will impact other personnel.

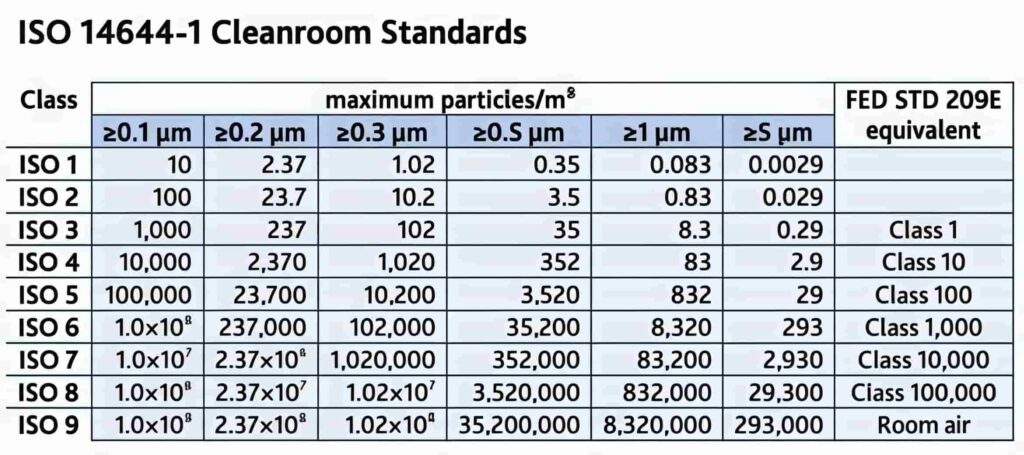

Regulatory and Performance Considerations (ISO 14644 Compliance)

Of course, the most important part of cleanroom construction is ensuring that your space is compliant with all regulatory and performance requirements. Depending on the space, retrofitting will often require changes, whether that’s changes to the air handling systems, changes to the space itself, or changes to other internal building systems. These changes are made so AVM can ensure that all code and performance requirements are met. On the other hand, starting from scratch with a new cleanroom construction can often look simpler, but it doesn’t always ensure an easier process to meet these requirements. The bottom line with regulatory and performance considerations is that the AVM team has the experience and the ability to handle any requirements for cleanroom construction, whether it’s a retrofit or a new build.

Cost, Timeline, And Operational Impact Comparison

When evaluating the budget, it can be tempting to think that retrofitting is always the most economical choice. In reality, the cost-per-square-foot for a new build can actually end up lower than a complex retrofit project. Because new construction allows for prefabricated materials and standardized workflows, these projects can often save time and money, while retrofits may involve more work to reach compliance levels and meet your project needs. This can potentially increase labor complexity and technical challenges. Every project is unique in its own right, and a thorough evaluation of existing systems as compared to available open space can help determine the most cost-effective approach.

When Retrofitting Makes Sense Vs. When A New Build Is Smarter

Choosing between a retrofit and a new build isn’t just a budget line item—it’s a strategic decision that dictates the long-term viability of your environment. At AVM, we take a comprehensive assessment of your goals before a single hammer swings because we are focused on doing what’s right for your space and your facility’s needs. We work with you to create the plan that works best for your budgets, environment needs, and overall strategy to ensure your satisfaction.

Here is how we help you weigh the two paths:

Retrofitting:

Retrofitting is often attractive for its potential cost savings, but it requires a high level of technical scrutiny. It’s not uncommon for general contractors and unspecialized companies to promise that existing systems will work, only to face system failures later. Retrofit considerations include:

- HVAC & Air Handling: The biggest hurdle for a retrofit system is often existing air handlers. While it’s possible to utilize current systems, achieving precise temperature control and high-level filtration requires a complex balancing act that isn’t always viable.

- Shared Plenum Issues: In some buildings, a shared plenum (the space used for air circulation) can be a dealbreaker. Retrofitting in these environments risks cross-contamination or pressure imbalances with neighboring spaces.

- Life Safety Compliance: Older structures often require significant upgrades to meet modern life safety codes. What looks like a simple retrofit can quickly turn into a major overhaul once safety requirements are factored in.

New Construction:

New builds often offer the luxury of a “friendly” environment designed specifically for your needs, though they come with their own set of variables.

- Space Selection: If the space for your new construction requires significant structural adaptation to fit your specific environmental needs, additional material fabrication time and added costs may make the timeline stretch, and costs can spiral, making a retrofit the better option.

- Simplified Execution: While the initial path to achieving your goals is usually more direct, other factors that are less common may pop up, complicating the construction process.

- Infrastructure Costs: With a new construction project, costs can potentially be higher due to the lack of existing infrastructure.

Overall, there is no straightforward answer to which option is better for a generalized space. Because AVM is focused on creating the space that fits your needs each and every time, we’ll work with you to determine the right choice for your specific facility.

How AVM Streamlines the Process for Both Options

When you work with AVM Group, the streamlining begins long before any construction starts. Because we handle everything from start to finish, we can take everything into account—from surveying an open space for a new build to analyzing the capacity of your current air handlers—to provide you with the full picture up front. Our team doesn’t believe in offering what isn’t right for our clients; if a retrofit isn’t a viable option for your technical goals, we will make sure you understand why.

Because we handle everything, from design and engineering to HVAC and life safety considerations, you bypass the typical finger-pointing or miscommunications that can happen when systems don’t align among multiple subcontractors and other technicians. We handle the complex load calculations and filtration requirements internally, too, ensuring that your existing systems aren’t just usable, but are truly capable of meeting your environmental standards.

While it would be ideal to be able to provide an exact formula for choosing an option, what’s important to remember is that every space is unique and every environment must meet strict standards. When AVM Group works with our clients, we take the time to understand your facility, the specific space, your system requirements, your budgeting and time constraints, and all other relevant information regarding your cleanroom construction. With this knowledge, our team is able to help you decide which works best for your facility and requirements.

Ultimately, the AVM Group approach to cleanroom construction is built on the belief that a successful project is rooted in technical honesty. By choosing a complete design-build partner who acts as a partner with your organization from the initial consultation, clients are investing in a process that prioritizes end-state goals over quick construction. Whether we’re maximizing the life of your current infrastructure through a precision retrofit or building a brand-new modular cleanroom, our commitment remains the same: to deliver a space that performs exactly as promised, on a budget that respects the reality of the work.