*This post is part of a much larger pillar blog: The Complete Guide to Controlled Environments, and is closely related to our ULPA Filter article.

Table of Contents

ToggleIntroduction

As a company specializing in cleanroom design and construction for decades, we understand the critical role that HEPA filters play in maintaining controlled, contaminant-free environments.

High-Efficiency Particulate Air (HEPA) filters are an indispensable component in industries where air purity is paramount, including pharmaceuticals, healthcare, and electronics.

In this article, we will explore what HEPA filters are (for commercial settings), how they work, their applications, and their benefits, offering expert insights gained from years of hands-on experience.

First up: what exactly is a HEPA filter?

What is a HEPA Filter?

A HEPA filter is designed to trap particles as small as 0.3 microns with 99.97% efficiency. This standard was established during World War II to protect military personnel from radioactive particles, but its usage has since expanded to various industries.

The ability to capture contaminants like dust, pollen, mold, bacteria, and even some viruses makes HEPA filters the gold standard for air purification, only beaten by the ULPA filter.

Here’s a picture of what a HEPA filter may look like:

Now that we know what a HEPA filter is, let’s check out how they work.

How does a HEPA Filter Work?

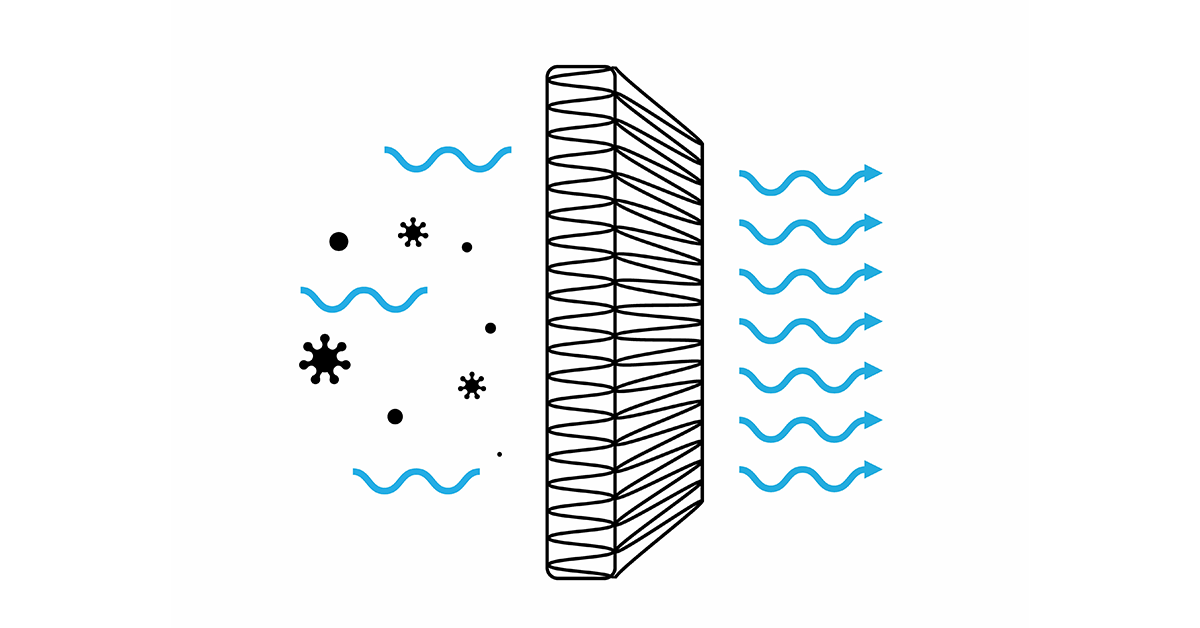

HEPA filters operate on three key principles: diffusion, interception, and impaction.

- Diffusion: Particles smaller than 0.1 microns move erratically due to collisions with gas molecules, which enhances their chances of being captured by the filter fibers.

- Interception: Larger particles moving along the airflow are intercepted and stick to the fibers as they come into close proximity.

- Impaction: Heavier particles with more momentum deviate from the air stream and impact directly onto the fibers.

This multi-layered mechanism enables HEPA filters to effectively capture a wide range of particle sizes without hindering airflow.

The Importance of HEPA Filters in Cleanrooms

It may be obvious by now, but HEPA filters are extremely important.

When looking at commercial environments like cleanrooms, particularly in pharmaceutical manufacturing or semiconductor production, air cleanliness is vital to prevent contamination that could compromise product integrity.

Hence, the need for HEPA filters. HEPA filters ensure that particles such as dust, bacteria, and even chemical fumes are kept at bay, maintaining the stringent standards required in these controlled environments. This can greatly help with quality control, and maintaining the integrity of your company’s process.

In fact, we actually made a video covering these two reasons, and more information. Check it out below!

Industry Standards

In some situations, HEPA filters aren’t just a luxury, they’re a legal requirement.

Certain industries with cleanroom mandates, such as ISO 14644-1, require that a certain number of filters be present to ensure the room meets spec.

A cleanroom that complies with these standards will typically incorporate a large number of HEPA or even ULPA (Ultra-Low Penetration Air) filters, which offer even finer filtration than HEPA.

Key Applications of HEPA Filters

While HEPA filters were originally designed for military use, their ability to purify air has made them essential in various sectors. In the coming paragraphs, we’ll talk about the three industries that most of our clients operate in.

Healthcare and Hospitals

Hospitals use HEPA filters to reduce the risk of airborne infections, especially in operating rooms, isolation wards, and laboratories.

These filters prevent the spread of pathogens like SARS-CoV-2 or MRSA, ensuring that both patients and healthcare professionals are protected.

Pharmaceutical Manufacturing

Pharmaceutical companies rely on cleanrooms equipped with HEPA filters to ensure that medications are produced in contaminant-free environments.

Any lapse in air purity can lead to compromised batches, costing both time and resources.

Aerospace and Semiconductor Manufacturing

The semiconductor industry requires the cleanest air possible to ensure that delicate components like microchips are not damaged during production.

Similarly, in aerospace engineering, the smallest particles can cause significant issues in the production of high-precision instruments.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of your industry with our weekly e-newsletter.

The Benefits of Using HEPA Filters

Now that we’ve talked about where HEPA filters are commonly employed, let’s look at why.

The benefits of using HEPA filters go beyond just capturing dust and debris.

Their use contributes to improved air quality, which can significantly impact health, comfort, and safety across various settings. Let’s go over some of the most common benefits in more detail.

Superior Air Quality

HEPA filters are capable of removing up to 99.97% of particles, including contaminants such as pollen, mold spores, and even some bacteria. This makes them ideal for environments where air quality is paramount, such as hospitals or research labs.

Allergy and Asthma Relief

For individuals suffering from allergies or asthma, HEPA filters can be life-changing. By removing airborne allergens, such as pollen and dander, HEPA filters reduce the number of irritants circulating in the air, leading to fewer allergy flare-ups and asthma attacks.

Improved Energy Efficiency

When properly maintained, HEPA filters can contribute to a more efficient HVAC system. By capturing contaminants, they prevent these particles from accumulating on HVAC components, which could otherwise reduce system performance and increase energy consumption.

Long Lifespan

Though HEPA filters are highly effective, they do require routine maintenance and replacement to continue functioning at optimal levels. However, with proper care, many HEPA filters can last between 2 to 3 years, depending on usage and environmental conditions.

Maintenance and Replacement of HEPA Filters

Like we mentioned, despite their high performance, HEPA filters can become clogged with particles over time, reducing their efficiency and potentially increasing energy costs.

Regular maintenance is essential to ensure they continue to provide high air quality.

But, how do you go about maintaining and replacing them?

Inspection

It’s critical to routinely inspect HEPA filters for any signs of wear, blockages, or damage. In industries like pharmaceuticals or electronics, where air purity is vital, this inspection should occur more frequently.

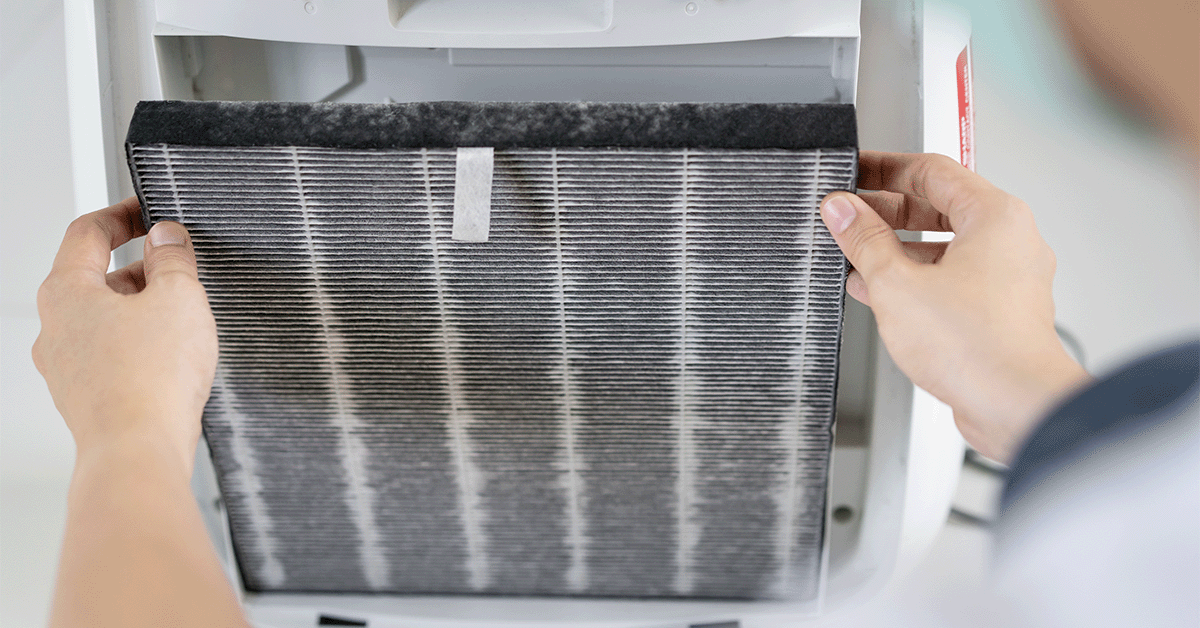

Here’s what a HEPA filter looks like when it’s more than likely ready for replacement.

Replacement Schedule

Although they can technically last up to 2-3 years, HEPA filters should typically be replaced every 6 to 12 months in high-demand environments such as cleanrooms.

Proper Disposal

HEPA filters must be disposed of properly, especially if used in healthcare settings or industrial applications where hazardous particles could have been captured. Most often, they are treated as hazardous waste.

Each company will have a different set of policies regarding hazardous waste, so please be sure to follow internal guidelines.

Common HEPA Filter Myths

Because of how popular HEPA filters are, there are a lot of myths and misconceptions that commonly pop up. Let’s prove those wrong, shall we?

Myth: All Air Filters are the Same

While many people assume all air filters serve the same purpose, this is far from true. HEPA filters have stringent efficiency standards and are far more effective at trapping smaller particles than regular filters.

The difference is not even close.

Myth: HEPA Filters Eliminate All Particles

Though HEPA filters capture the vast majority of contaminants, no air filter can eliminate 100% of particles. For instance, gases and certain chemicals may require additional filtration methods like activated carbon filters.

Every business have different needs, so make sure to work with the right controlled environment company to ensure you cover all of your bases when it comes to filtration.

Myth: HEPA Filters Don’t Need to Be Replaced

One common misconception is that because HEPA filters are high-quality, they don’t need replacement. However, failing to replace a HEPA filter regularly can reduce its effectiveness and even cause damage to other parts of your HVAC system or cleanroom.

We talked about this a bit above, but it is important to mention it again.

Conclusion

HEPA filters are indispensable in maintaining the cleanliness and air purity required in many industries. Their ability to remove a wide range of contaminants ensures that environments—from cleanrooms to other commercial spaces—remain safe, healthy, and free from harmful particles.

Whether in a healthcare setting, a pharmaceutical lab, or a manufacturing facility, understanding the capabilities and maintenance of HEPA filters is crucial for ensuring their longevity and performance.

With decades of experience in cleanroom technologies, we recommend regular maintenance, correct installation, and the use of certified HEPA filters to meet the highest air quality standards.

From improving industrial processes to enhancing everyday health, HEPA filters remain a critical component of modern air purification systems.

Need help with your HEPA filters? Contact us.