*This post is part of a much larger pillar blog: The Ultimate Radiation Shielding Guide

Table of Contents

ToggleIntroduction

Radiation shielding is crucial for protecting individuals and the environment from the harmful effects of radiation.

Effective shielding is essential in various settings, including medical facilities, industrial applications, and research laboratories.

Proper shielding ensures that radiation exposure remains within safe limits, preventing potential health risks and ensuring compliance with regulatory standards.

This article aims to provide an in-depth comparison of lead vs. concrete as radiation shielding materials.

By evaluating the cost, effectiveness, and practical considerations of both materials, we seek to help readers make informed decisions for their shielding needs.

Let’s begin by reviewing some basics of how radiation shielding works.

The Basics of Radiation Shielding

Radiation shielding protects those in and around it through three key methods: attenuation, absorption, and scattering. If you’re unaware of what those terms mean, we’ve spelled it out for you below.

- Attenuation: The reduction of radiation intensity as it passes through a material.

- Absorption: The process by which the shielding material absorbs radiation energy.

- Scattering: The deflection of radiation away from its original path once it collides with a material, which can also reduce radiation intensity and complicate things shielding wise.

Now that we’ve talked about these terms a little bit, let’s look at the differences between how lead and concrete tackle these methods.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of the shielding industry with our weekly e-newsletter.

Overview of Lead Shielding

First up, lead. Lead is one of the most popular radiation shielding materials. How dense lead is as a material. This allows you to reduce the thickness of the shielding required.

In the next few sections, we’ll discuss the key properties of lead, and how those properties impact lead’s shielding effectiveness.

Properties of Lead

- High Density: Lead’s high density and high atomic number makes it extremely effective at attenuating gamma rays and X-rays.

- Malleability and Ease of Fabrication: Lead can be easily shaped and fabricated into various forms, making it versatile for different applications.

Effectiveness of Lead Shielding

- Attenuation Coefficients: Lead has high attenuation coefficients for gamma rays and X-rays, meaning it is highly effective at reducing radiation intensity.

- Thickness Requirements: Due to its density, lead requires relatively less thickness compared to other materials, providing big benefits to companies with space constraints.

Overview of Concrete Shielding

Now that we’ve covered lead in great detail. It’s time to talk about concrete, and it’s use as a radiation shielding material. We’ll take a look at the same topics to make sure the comparison to lead at the end of this article is fair.

Properties of Concrete

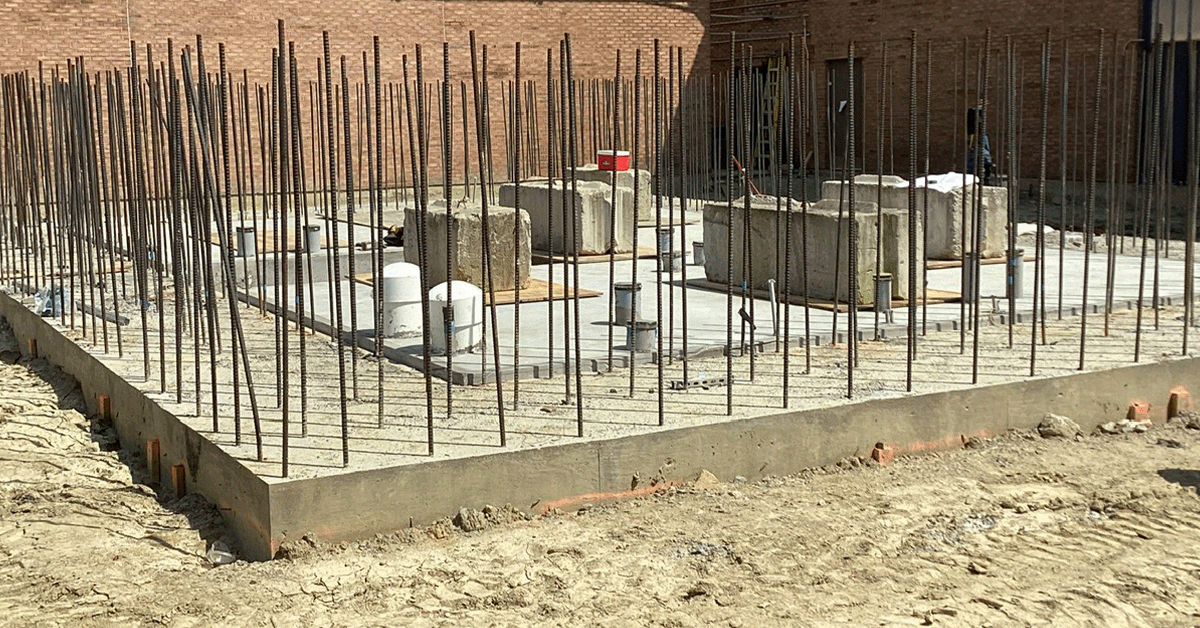

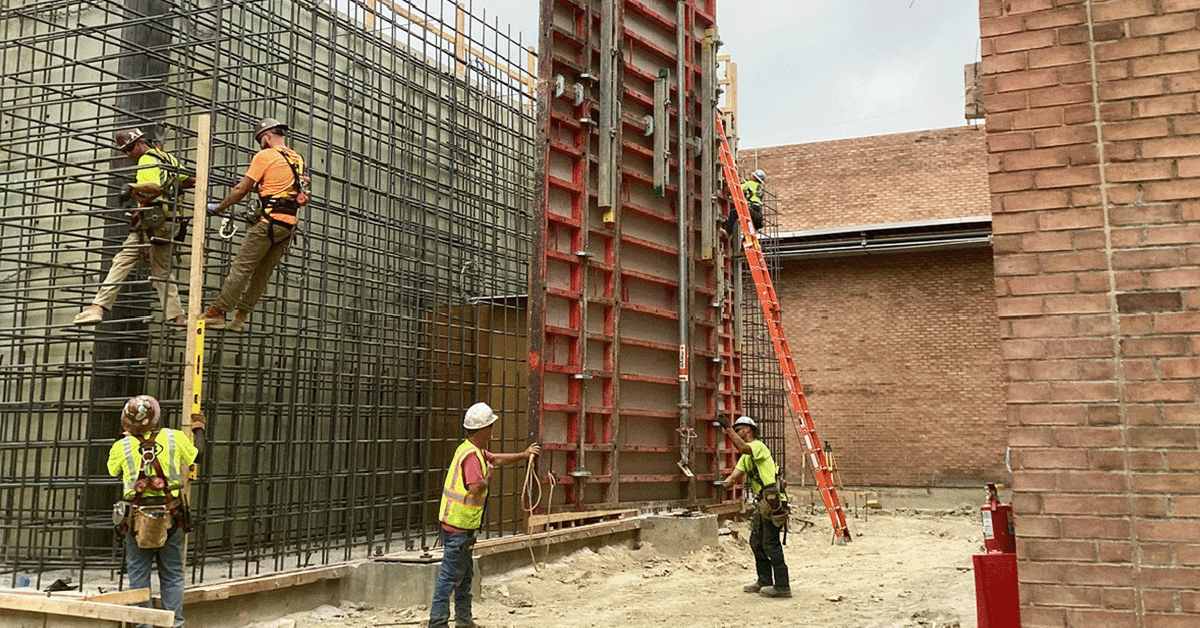

- Composition: Concrete is made from cement, aggregates (such as sand and gravel), and water.

- Density Variations: Standard concrete can be enhanced with heavy aggregates to create high-density concrete, improving its shielding capabilities.

- Structural Strength and Versatility: Concrete is robust and versatile, suitable for constructing large and complex shielding structures.

- Cost Effectiveness: Concrete in most cases is more affordable than lead, particularly for higher shielding situations.

Effectiveness of Concrete Shielding

- Attenuation Coefficients: Concrete has good attenuation properties for different types of radiation.

- Thickness Requirements: Concrete requires greater thickness than lead due to its density properties to achieve equivalent shielding, which can be a consideration in design and construction.

Comparing Lead vs Concrete for Radiation Shielding

We’ve discussed in great detail both of these two excellent shielding materials, so now it’s time to compare them.

We will be looking at six key areas: density and attenuation, thickness and space requirements, cost considerations, ease of installation and maintenance, environmental and health impact, and practical applications and suitability.

Density and Attenuation

- Lead: Lead’s high density makes it particularly effective for gamma and X-ray shielding. It provides substantial attenuation with relatively thin layers.

- Concrete: Concrete, while less dense than lead, can be used effectively for neutron shielding and gamma rays when designed with adequate thickness. High-density concrete improves its performance but still generally requires more thickness compared to lead.

Thickness and Space Requirements

- Lead: Because of its high density, lead can achieve significant radiation attenuation with minimal thickness, making it ideal for space-constrained environments.

- Concrete: Concrete’s lower density means it requires thicker layers to provide the same level of shielding as lead. This can be a disadvantage in terms of space utilization and weight, particularly in smaller facilities.

Cost Considerations

- Lead: The initial cost of lead is higher due to the material itself and the need for specialized handling and installation. However, lead can be recycled, which may offset some costs in the long term.

- Concrete: Concrete is generally less expensive than lead, especially for large-scale applications. The cost includes materials and construction, but the overall expense is usually lower compared to lead.

Ease of Installation and Maintenance

- Lead: Lead is flexible and can be installed relatively quickly, but it requires precautions due to its toxicity. Specialized handling and safety measures are necessary.

- Concrete: Concrete installation is more labor-intensive and requires significant structural support. Once installed, concrete is durable and requires minimal maintenance.

Environmental and Health Impacts

- Lead: Lead poses health risks due to its toxicity. Handling and disposal must be managed carefully to avoid environmental contamination. Proper safety protocols are essential.

- Concrete: Concrete is non-toxic and environmentally friendly when produced using sustainable practices. It does not pose significant health risks during handling or disposal.

Practical Applications and Suitability

- Lead: Lead is ideal for applications requiring high levels of shielding in confined spaces, such as medical imaging rooms and mobile shielding solutions.

- Concrete: Concrete is best suited for permanent, large-scale installations where space is less of a concern, such as nuclear power plants and particle accelerators.

Regulatory and Safety Concerns

By this point in the article, you may have made up your mind about which material you want to move forward with. If so, that’s great!

However, safety is always top priority, so make sure to read the following section for best practices on construction and handling.

Regulatory Standards for Radiation Shielding

- International and National Guidelines: Both lead and concrete must meet specific regulatory standards for radiation shielding. These guidelines ensure that shielding materials provide adequate protection and comply with safety requirements. These are directed by state-specific regulations taken into consideration by physicists and designers.

- Specific Requirements for Lead and Concrete:Regulations specify the required thickness, installation methods, and safety measures for using lead and concrete as shielding materials. Compliance is essential to ensure the safety of personnel and the environment.

Safety Protocols and Best Practices

- Handling and Installation of Lead Shielding: Due to lead’s toxicity, handling and installation must follow strict safety protocols. Personal protective equipment (PPE) and proper ventilation are necessary to minimize exposure.

- Construction and Maintenance of Concrete Shielding: Concrete shielding construction requires careful planning and execution to ensure structural integrity and effective radiation protection. Routine inspections and maintenance are essential to ensure long-term performance.

- Monitoring and Verification of Shielding Effectiveness: Regular monitoring and verification of shielding effectiveness are crucial. This includes using radiation detectors to measure exposure levels and ensure that the shielding meets regulatory standards.

Conclusion

In comparing lead vs. concrete for radiation shielding, we have examined their properties, effectiveness, cost, and practical considerations.

Lead offers high-density, effective shielding with minimal thickness but comes with higher costs and handling precautions.

Concrete provides a cost-effective, versatile solution for large-scale applications but requires greater thickness and structural support.

Choosing between lead and concrete depends on specific project requirements, including space constraints, budget, and the type of radiation to be shielded.

Lead is ideal for confined spaces and mobile solutions, while concrete is suitable for permanent installations where space is less of a concern.

Prioritizing safety and compliance with regulatory standards will ensure effective radiation protection and long-term success for your project.

As always, before starting any project make sure to consult a licensed radiation shielding expert. More often than not, they’ll see factors specific to your project that you may have missed. It is always worth the investment to work with a team that knows what they’re doing.

Ready to construct a new shielding structure? Contact us.