*This post is part of a much larger pillar blog: The Complete Guide to Controlled Environments

Table of Contents

ToggleIntroduction

In environments where contamination control is of paramount importance, the role of cleanroom pass-throughs cannot be understated.

Much like cleanroom furniture and cleanroom air showers, cleanroom pass-throughs are a vital cleanroom component.

Pass-throughs play a pivotal role in maintaining sterility while facilitating the transfer of materials and equipment between different controlled environments, or between controlled and uncontrolled spaces.

In this article, we delve into the world of cleanroom pass-throughs, exploring their significance, functionality, benefits, challenges, and the future of this technology.

Let’s get into it.

Introduction to Cleanroom Pass-Throughs

Before we get into the brass tacks of this article, it’s important to fully understand why cleanroom pass-throughs are so important, and what purpose they serve.

Understanding the Significance of Contamination Control in Controlled Environments

In industries such as pharmaceuticals, electronics, and healthcare, maintaining contamination-free environments is essential.

Contaminants can lead to product defects, compromise research, and risk patient safety.

Cleanroom pass-throughs act as gateways, preventing the spread of contaminants from one area to another. They are a very important part of a much larger controlled environment.

The Role of Cleanroom Pass-Throughs in Maintaining Sterility

Cleanroom pass-throughs serve as a conduit for transferring materials, tools, and equipment between controlled environments without compromising the sterility of either side.

This is crucial for ensuring the integrity of products and research outcomes by eliminating the possibility of particulates entering the space during transfer.

Okay, now that you understand why they’re so important, let’s go into what exactly cleanroom pass-throughs are.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of your industry with our weekly e-newsletter.

What are Cleanroom Pass-Throughs?

In this section, we’ll go over the definition and basic functionality of a cleanroom pass-through.

Definition and Basic Functionality of Cleanroom Pass-Throughs

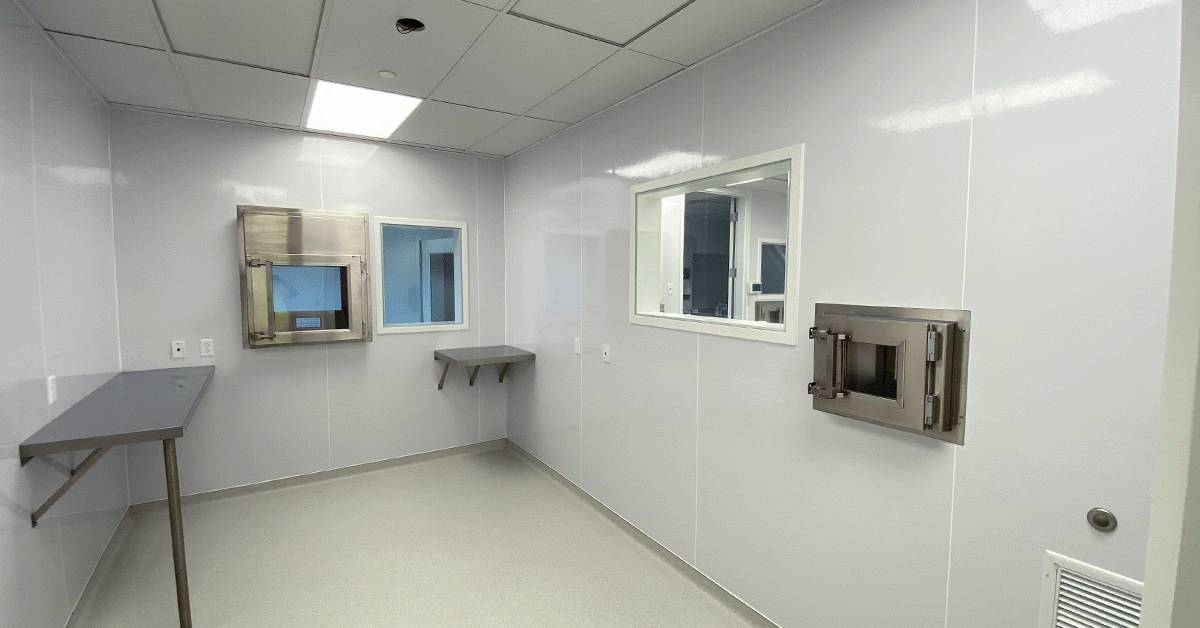

Cleanroom pass-throughs are specialized chambers or mechanisms that enable the transfer of materials and equipment between cleanrooms or controlled environments. Consider a pass-through as a smaller, more cost-effective version of an anteroom that allows the transfer of personnel and larger equipment.

They maintain the separation of spaces while allowing controlled access.

By creating this sealed separation barrier between cleanroom spaces, pass-throughs prevent direct contact between personnel and contaminants, reducing the risk of cross-contamination.

What smaller components make up a pass-through?

Components of a Cleanroom Pass-Through

The biggest factors to consider when looking at what components make up a cleanroom pass-through are the materials used to construct the structure and inside of the pass-through, and the door that creates the separation barrier we talked about earlier.

Pass-Through Material Choices

Cleanroom pass-throughs come in various materials, including stainless steel, acrylic, polypropylene, and glass, each offering distinct benefits in terms of durability, ease of cleaning, and resistance to chemicals.

Usually, pass-throughs are installed towards the end of the controlled environment construction, so you would be best served to match the material of the pass-through to what you’ve used in the rest of the cleanroom for continuity.

Door Mechanisms

Different door mechanisms, such as interlocking, mechanical, and automated systems, are utilized in cleanroom pass-throughs to maintain airlock integrity and minimize contamination transfer.

The type of door mechanism you choose will mainly is more a matter of cost, and desire for access control, like a badged access.

Now that we know what makes up pass-throughs, what design decisions need to be taken into consideration?

Design Considerations for Cleanroom Pass-Throughs

The biggest factors that are considered during the design process is the location of the pass-through itself, and the size of the object being transferred.

Size and Dimensions Based on Equipment/Materials to Be Transferred

Pass-through dimensions are tailored to accommodate the specific equipment, tools, or materials that need to be transferred, ensuring a seamless process.

It’s important to understand the cleanroom process and materials being handled to size the pass-through appropriately.

Wall-Mount vs. Floor-Mount Pass-Throughs: Pros and Cons

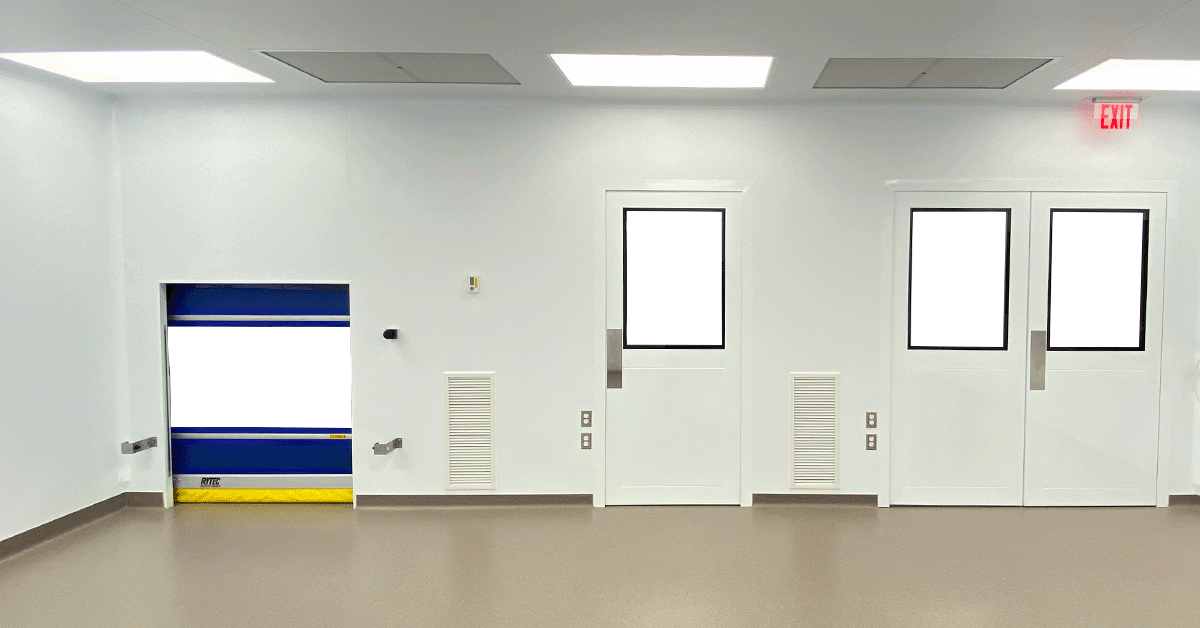

The choice between wall-mounted and floor-mounted pass-throughs depends on the available space, workflow requirements, and the need for flexibility in cleanroom layout.

Past a certain size, a floor mounted pass through may be the right choice, as they can accommodate lab carts, and batched quantities of material.

If you choose the right team to build your controlled environment, they will have taken these into account when designing your room.

Customization and Special Features

Cleanroom pass-throughs are not cookie cutter. Each one we build has a set of special considerations that need to be incorporated.

Tailoring Pass-Throughs to Specific Cleanroom Needs

Cleanroom pass-throughs can be customized to meet the unique requirements of different industries and applications.

Your cleanroom construction team should know this, and will have implemented these requirements from the beginning.

Additional Features

To enhance contamination control, pass-throughs can be equipped with features such as UV sterilization, air curtains, and HEPA and ULPA filtration systems, and cooling systems for refrigerated specimens.

Installation and Integration

Now that you have all necessary planning done for your cleanroom pass-through, let’s talk about how we make sure the installation and integration is done properly.

Proper Installation to Maintain Cleanliness and Airtight Seals

Correct installation is critical to maintaining the integrity of the cleanroom environment.

Correct installation involves ensuring airtight seals remain intact on the doors, and proper alignment takes place into the wall.

Integration with Cleanroom Infrastructure

When installing a pass-through, we always make sure that it fits perfectly with the already in-place cleanroom components.

Pass-throughs are integrated into the overall cleanroom infrastructure which includes walls, doors, and airlocks.

Maintenance and Cleaning

Keeping a controlled environment requires consistent, calculated maintenance.

If this is too hard for your organization to keep up with, contact us. We perform cleanroom maintenance for a wide variety of our customers.

Regular Maintenance Routines for Pass-Throughs

Routine maintenance is essential to keep pass-throughs in optimal working condition and to ensure that they continue to provide effective contamination control.

Each company will have a different maintenance checklist to follow, so it’s important to stay up to date with your organization’s standards.

Cleaning Protocols to Uphold Cleanliness and Sterility

Proper cleaning protocols prevent the buildup of contaminants and maintain the sterility of pass-throughs, contributing to overall cleanroom hygiene.

Specific chemicals and cleaning techniques should be utilized, but make sure to check with your controlled environment manager to ensure you’re using the proper chemicals.

Common Challenges in Using Pass-Throughs

We’ve talked extensively about the benefits of using a cleanroom pass-through, but it’s very important to highlight some common challenges, to give you a more holistic view of what you should expect.

Potential Points of Failure and Contamination Risks

While highly effective, cleanroom pass-throughs can present challenges such as mechanical failures or breaches in airlock integrity, leading to potential contamination risks.

This is one of the biggest reasons you need to keep up on your maintenance.

Strategies for Troubleshooting and Addressing Issues

Having a robust troubleshooting plan in place, along with regular inspections, can help identify and address issues promptly.

This is where proper cleanroom monitoring and logging comes into place.

Future Trends in Cleanroom Pass-Through Technology

What are some of the ways that cleanroom pass-throughs are evolving?

Emerging Technologies and Innovations in Pass-Through Design

Advancements in pass-through technology include improved door mechanisms, more intuitive control systems, and better integration with cleanroom automation.

Integration with IoT and Automation for Enhanced Control

The future holds the potential for cleanroom pass-throughs to be seamlessly integrated into Internet of Things (IoT) networks and automated workflows.

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of your industry with our weekly e-newsletter.

Cost Considerations and ROI

We know it’s on your mind. Let’s discuss cleanroom ROI for pass-throughs.

Initial Investment vs. Long-Term Benefits

While cleanroom pass-throughs require an upfront investment, their long-term benefits in terms of contamination control and operational efficiency far outweigh the initial costs.

Calculating Return on Investment for Cleanroom Pass-Throughs

Calculating the ROI of cleanroom pass-throughs involves considering factors such as reduced downtime, enhanced product quality, and regulatory compliance.

Figuring out the ROI is extremely important, and also extremely specific to your business and your production process.

Cleanroom Pass-Through FAQs

What are some of the most asked questions regarding cleanroom pass-throughs we get from our clients?

GET THE LATEST INDUSTRY NEWS DELIVERED TO YOUR INBOX

Stay on the forefront of your industry with our weekly e-newsletter.

What Industries Benefit from Cleanroom Pass-Throughs the Most?

Cleanroom pass-throughs are most beneficial for industries where contamination control is critical, such as pharmaceuticals, biotechnology, and electronics manufacturing.

Are There Size Limitations for Pass-Throughs?

Cleanroom pass-throughs can be customized to accommodate various sizes of equipment and materials, with considerations for workflow efficiency.

In terms of practicality, and as material transferred and batch sizes increase, consider upsizing from a wall to a floor mounted pass-through, or from a floor mounted pass-through to a full size material transfer room.

How Do Pass-Throughs Maintain a Sterile Environment

Pass-throughs maintain a sterile environment by creating a sealed barrier between cleanrooms, preventing the transfer of contaminants.

Can Pass-Throughs Be Retrofitted into Existing Cleanrooms?

Yes, cleanroom pass-throughs can be retrofitted into existing cleanrooms, provided there is sufficient space and integration can be executed without compromising cleanroom integrity.

Conclusion

Cleanroom pass-throughs play an indispensable role in maintaining contamination-free environments across various industries.

From their materials and design considerations to their benefits and challenges, these systems are pivotal in enhancing operational efficiency and ensuring product quality.

As technology continues to evolve, cleanroom pass-throughs are set to become even more advanced, solidifying their status as a cornerstone of contamination control in controlled environments.

If you’re wanting to install a new cleanroom pass-through, or controlled environment, contact us.